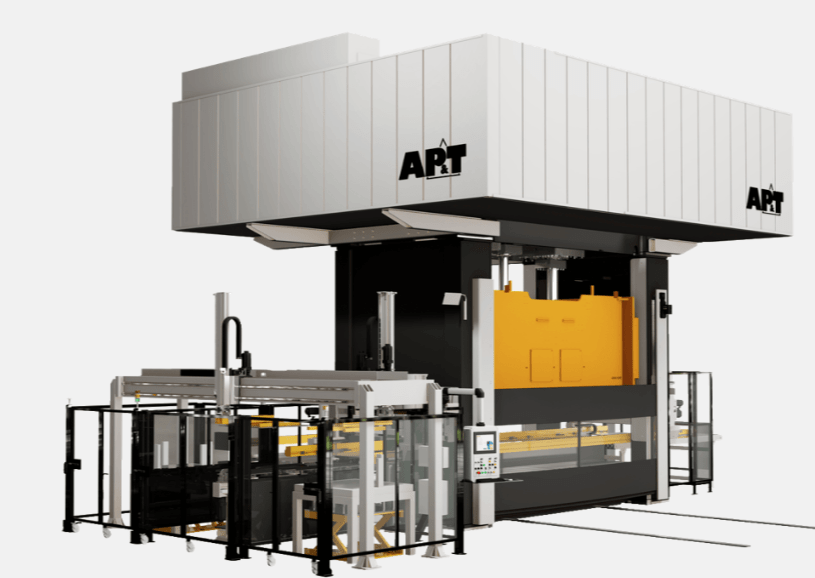

With the introduction of its unique servo hydraulic press, AP&T has set a new standard in the industry. Short cycle times, high precision, low energy consumption and minimum need for maintenance make this option hard to beat — not only compared to conventional hydraulic presses, but in many cases also compared to servo mechanical presses.

AP&T’s servo hydraulic press is not only quicker and more energy efficient than conventional hydraulic presses, it is also a powerful alternative to servo mechanical presses.

Several innovative technical solutions have helped AP&T’s designers combine high performance with low operating costs. First and foremost, the hydraulic system’s control valves have been replaced by servo motors, which means that speed, position and press force are completely controlled electrically.

“The design has made it possible to limit the number of unique moving parts, cut down on oil volume, reduce pressure in the hydraulic system to a maximum of 250 bar and eliminate the effects of any variations in oil temperature. This lays the foundation for a very robust process with a high degree of availability and repeat accuracy, at the same time that the need for maintenance is substantially reduced,” says AP&T’s Product Manager Presses Patrik Haglund.

The servo motor solution has also streamlined energy consumption by between 40 and 70 percent, depending on the application. Heat loss generated by pressure valves can be avoided, and some servo motors are used as generators at retardation. The press’ cushion cylinder is also operated by servo motors which work as generators. Braking energy is distributed to the motors used for acceleration and forming through a kinetic storage system and a central direct current converter. Since the energy is stored internally in the press, it is not necessary to use electricity from the grid during peak loads, which results in a lower connection fee. Stored energy surpluses can also be restored to the grid.

With high stroke frequency, full synchronization and compensation for off-center loads, AP&T’s servo hydraulic press is well suited to transfer solutions.

The entire press process is monitored by a closed-loop system, which continuously controls the slide’s movements, quickly corrects any deviations and ensures speed and position with a great deal of precision. Not least, the system actively governs the slide’s parallelism in relation to the press table — a unique integrated function that contributes to both high forming precision and less wear on tooling.

“The acceleration and retardation speed is an impressive two to three times higher than that of a conventional hydraulic press, thus enabling extremely short cycle times. To maximize production capacity, the press can be synchronized with other servo-driven units for feeding and unloading,” says Patrik Haglund.

Low energy consumption, compact design, high production capacity and repeat accuracy in combination with low maintenance costs make AP&T’s servo hydraulic press a competitive alternative in several areas that have traditionally used mechanical presses.

AP&T’s servo hydraulic press — examples of suitable applications

- Transfer solutions: High stroke frequency (SPM) compensates off-center loads and offers full synchronization.

- Deep drawing and other cold forming: High degree of control accuracy, pre-acceleration of cushion, pulsating forming and major energy savings.

- Forming of high-strength steel (AHSS): All forming in one step, reduced spring back, high forming forces on a small tooling area.

- Hot forming of aluminum: Minimal energy consumption at long holding times and high force, short cycle time, high forming speed.

- Press hardening: Minimal energy consumption at long holding times and high force, short cycle time, high forming speed.

- Lead press in tandem lines: Short cycle time for the entire line, full synchronization, flexible power/stroke length through the entire press cycle.

- Forming of composites and similar materials: Minimal energy consumption at long holding times and high force, ensured parallelism and flexible force patterns of the tool.

Leave A Comment

You must be logged in to post a comment.