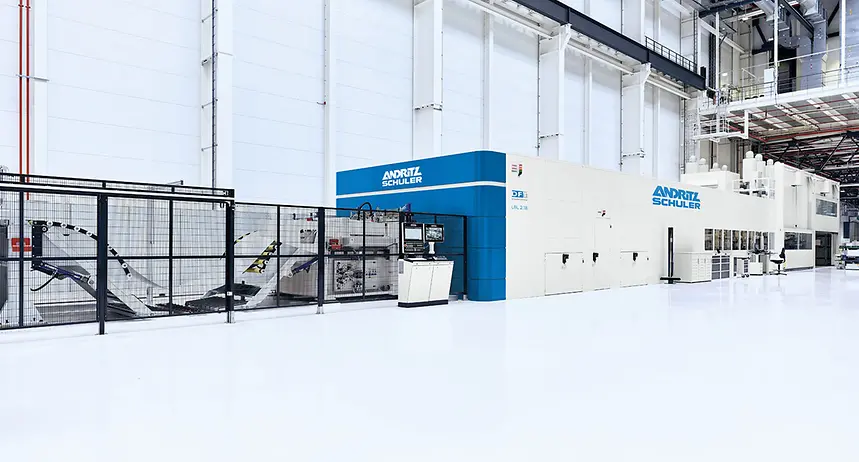

ANDRITZ Schuler, a leader in single presses and laser solutions, introduces the latest innovation in cut-to-length technology.

The Laser Blanking Line 1.18 DFT promises substantial benefits compared to conventional cut-to-length lines with shears, because it reduces the number of work steps and increases material utilization. The system’s ability to produce also unique parts next to trapezoids and rectangular blanks ensures ongoing operational efficiency and flexibility.

With this laser blanking line, for example in the area of steel service centers, additional shaped parts or cut-outs and holes can be cut directly into the blanks in a single work step, so that a subsequent additional work step for cutting master blanks is no longer necessary. Furthermore, the newly developed system offers substantial material savings through intelligent cross cuts that align more closely with the required final blank shapes, maintaining high output rates of up to 45 parts per minute depending on the geometry.

Highlighted in yellow: Additional scrap when using a trapezoidal cut with die technology. Material savings with intelligent cross-section thanks to DFT technology: 17%

Laser blanking nesting with intelligent cross cut close to the final required part shape, which means that almost no scrap is produced.

The Laser Blanking Line 1.18 DFT is capable of handling materials ranging from 0.6 to 6 mm in thickness directly from the coil, supporting steel, aluminum, and stainless steel – including high-strength materials over 1000 MPa, which can often lead to process-related difficulties with mechanical die systems. The new line concept eliminates the need for complex foundation work and cable trays in the floor as well as for a loop pit. With a length of approximately 25-30 meters, the line is only about half the size of a conventional cut-to-length line with a shear and thus offers optimized space utilization.

“With approximately 200 blanking lines and 24 laser blanking lines worldwide, ANDRITZ Schuler has cemented its position as blanking technology leader over the past years,” says Jürgen Funk, Director Global Blanking Lines at ANDRITZ Schuler . “The introduction of the Laser Blanking Line 1.18 DFT reinforces ANDRITZ Schuler’s commitment to innovation and excellence.”

Next to trapezoids and rectangular blanks, the Laser Blanking Line 1.18 DFT can also produce unique parts in an optimized spatial environment.

ANDRITZ GROUP

International technology group ANDRITZ provides advanced plants, equipment, services, and digital solutions for a wide range of industries, including pulp and paper, metals, hydropower, environmental, and others. Founded in 1852 and headquartered in Austria, the publicly listed group employs about 30,000 people at 280 locations in over 80 countries.

As a global leader in technology and innovation, ANDRITZ is committed to fostering progress that benefits customers, partners, employees, society, and the environment. The company’s growth is driven by sustainable solutions enabling the green transition, advanced digitalization for highest industrial performance, and comprehensive services that maximize the value of customers’ plants over their entire life cycle. ANDRITZ. FOR GROWTH THAT MATTERS.

ANDRITZ METALS

ANDRITZ Metals is – via ANDRITZ Schuler – one of the world’s leading suppliers of technologies, plants and digital solutions in metal forming. The product portfolio also includes automation and software solutions, process know-how and service. In the metals processing segment, the business area offers innovative, sustainable and market-leading solutions for the production and processing of flat products, for welding systems and furnaces with its own burner solutions, as well as services for the metals processing industry.

Leave A Comment

You must be logged in to post a comment.