Bruderer completes landmark ‘centre of manufacturing excellence’ in Telford

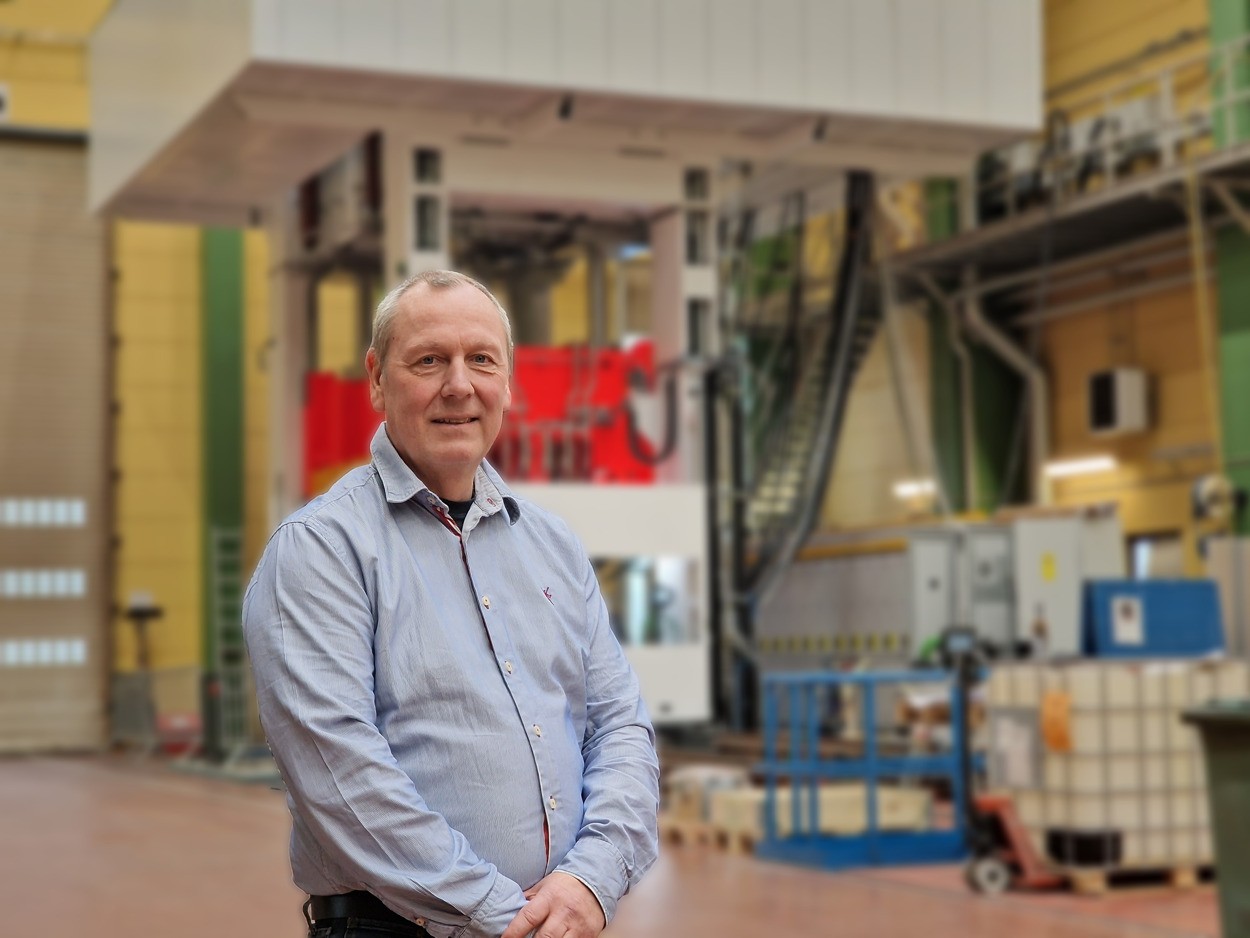

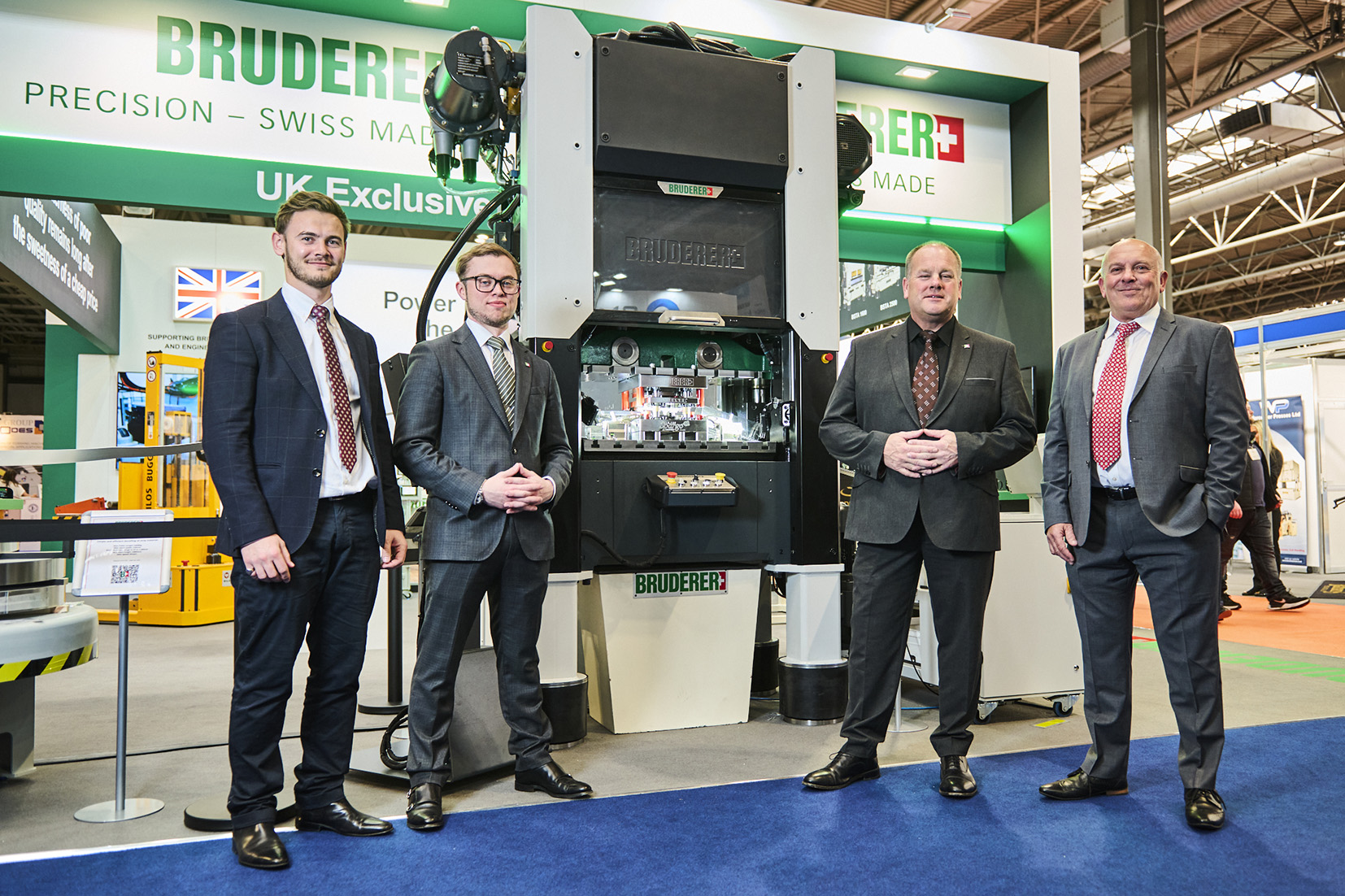

In a landmark move for UK industry, a new 10,000 sq metre ‘centre of manufacturing excellence’ has opened in the home of the industrial revolution. Bruderer, the world’s leading manufacturer of precision high-speed presses, has reinforced its commitment to [...]