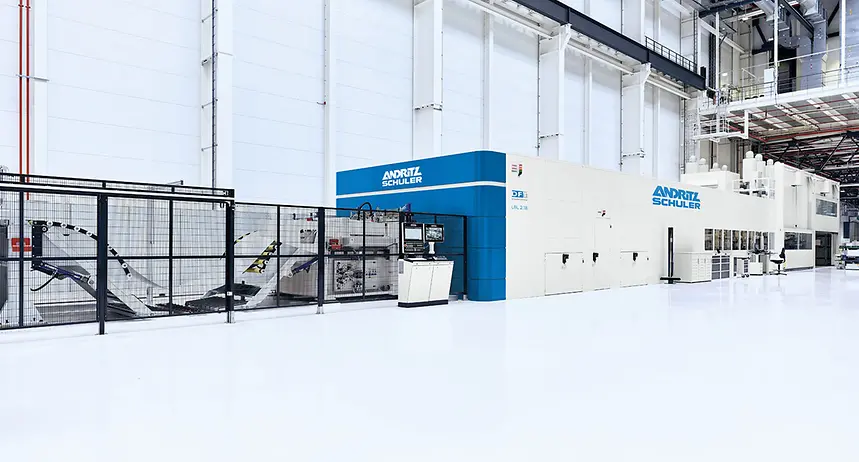

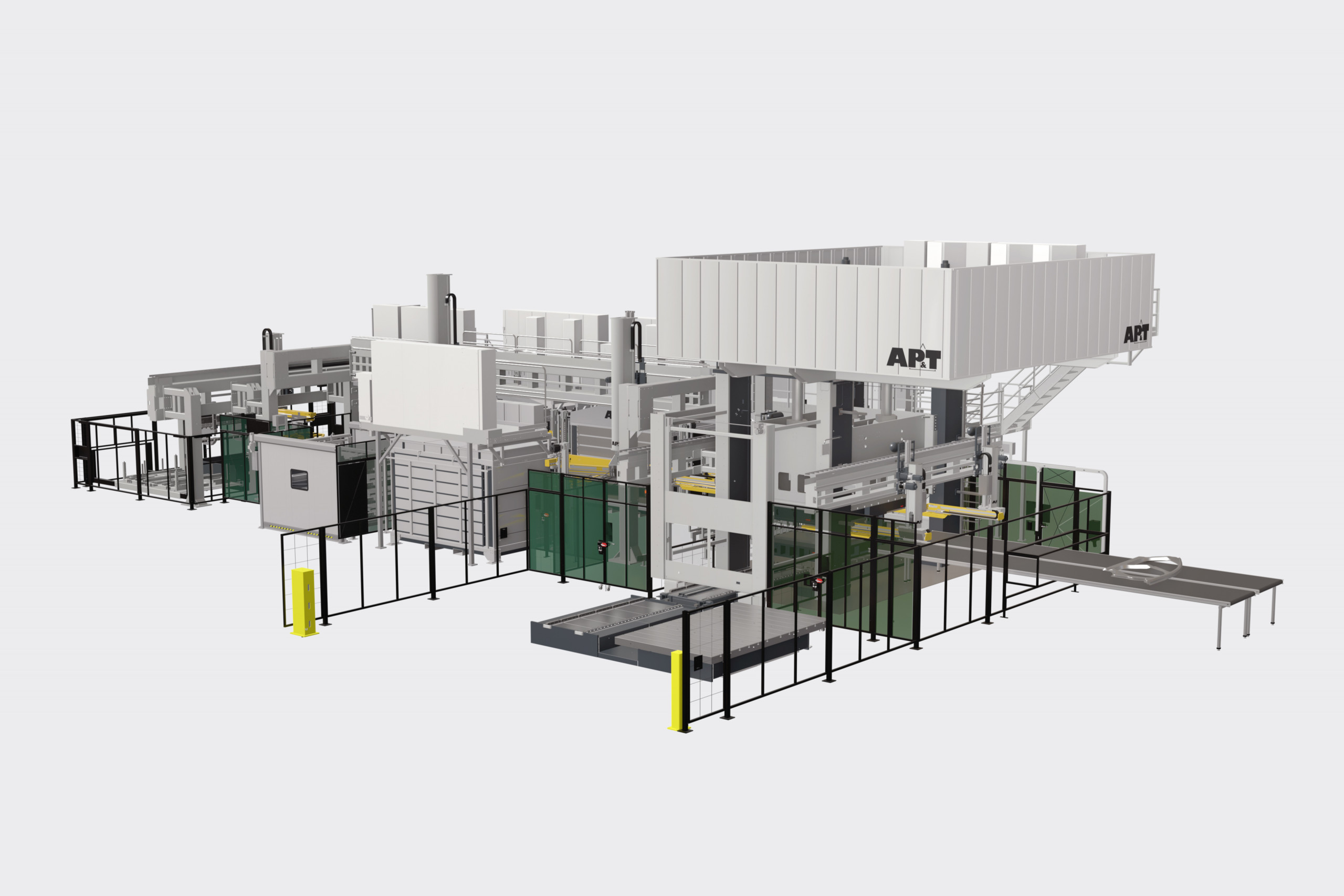

Metris Visual Die Protection monitors car body production in the Smart Press Shop

GRAZ, JULY 03, 2025. In the production of body parts, the quality of the dies is of paramount importance. Even the smallest errors, such as defective dies or tooling elements, scrap accumulation, or cracks in the components, can cause [...]