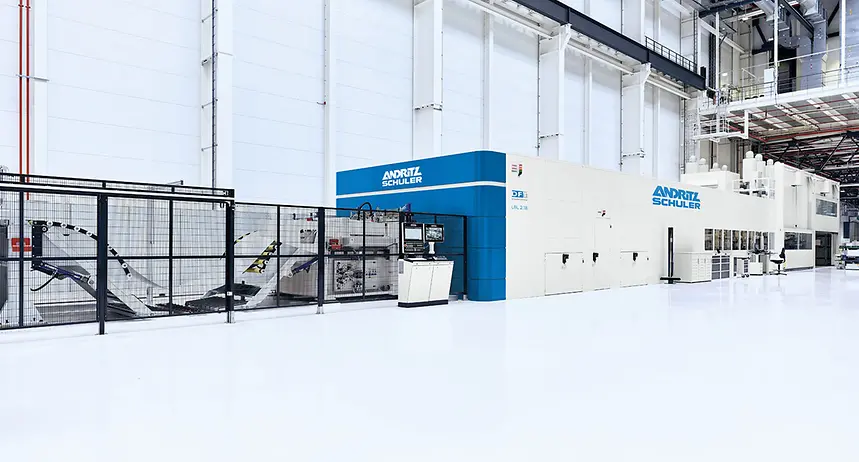

ANDRITZ Schuler Develops Innovative Laser Technology for Cut-to-Length-Lines

ANDRITZ Schuler, a leader in single presses and laser solutions, introduces the latest innovation in cut-to-length technology. The Laser Blanking Line 1.18 DFT promises substantial benefits compared to conventional cut-to-length lines with shears, because it reduces the number of [...]