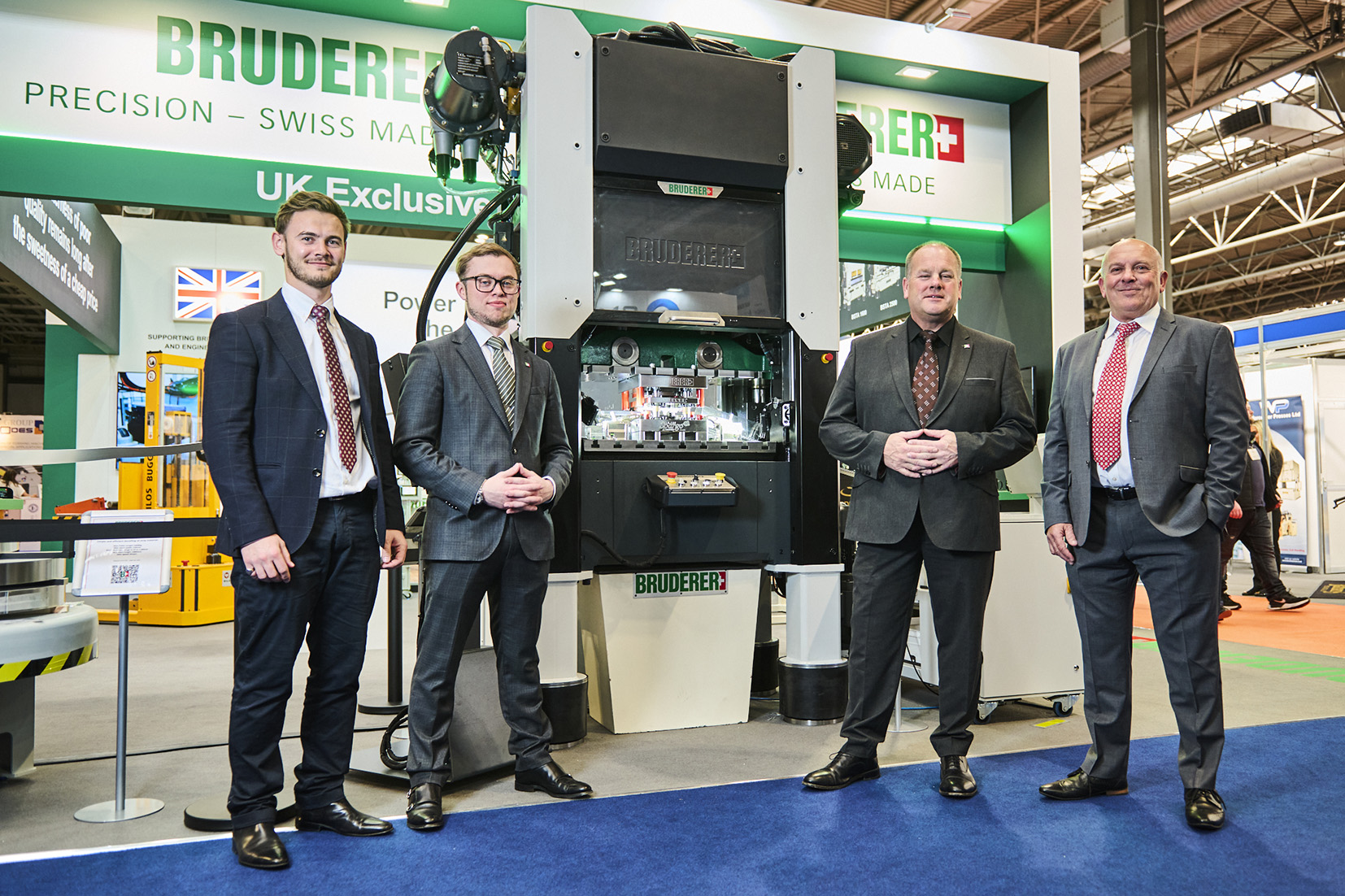

Match made in tooling leads to press investment at MACH 2024

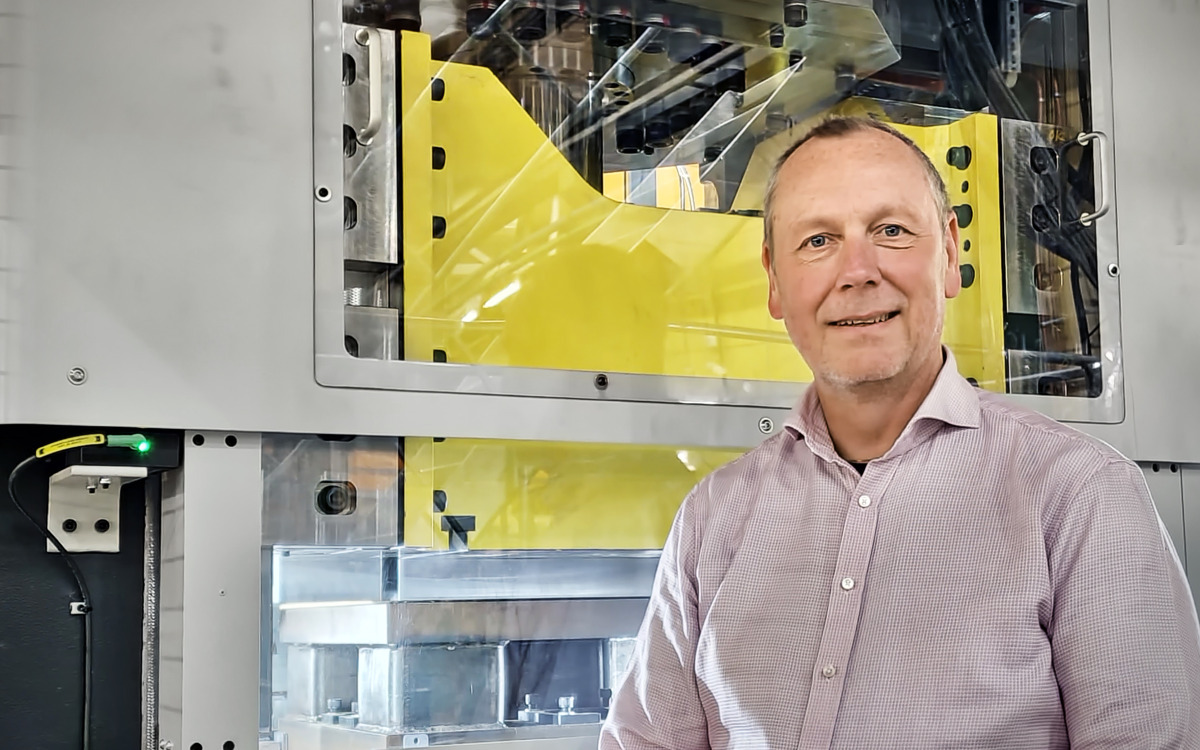

A specialist supplier to F1, automotive and aerospace sectors is looking to increase its tool try-out capacity by purchasing its first Bruderer press at MACH 2024. Alan Spargo Ltd, which celebrates 50 years in business in 2025, has invested [...]