Press shops are not working to capacity

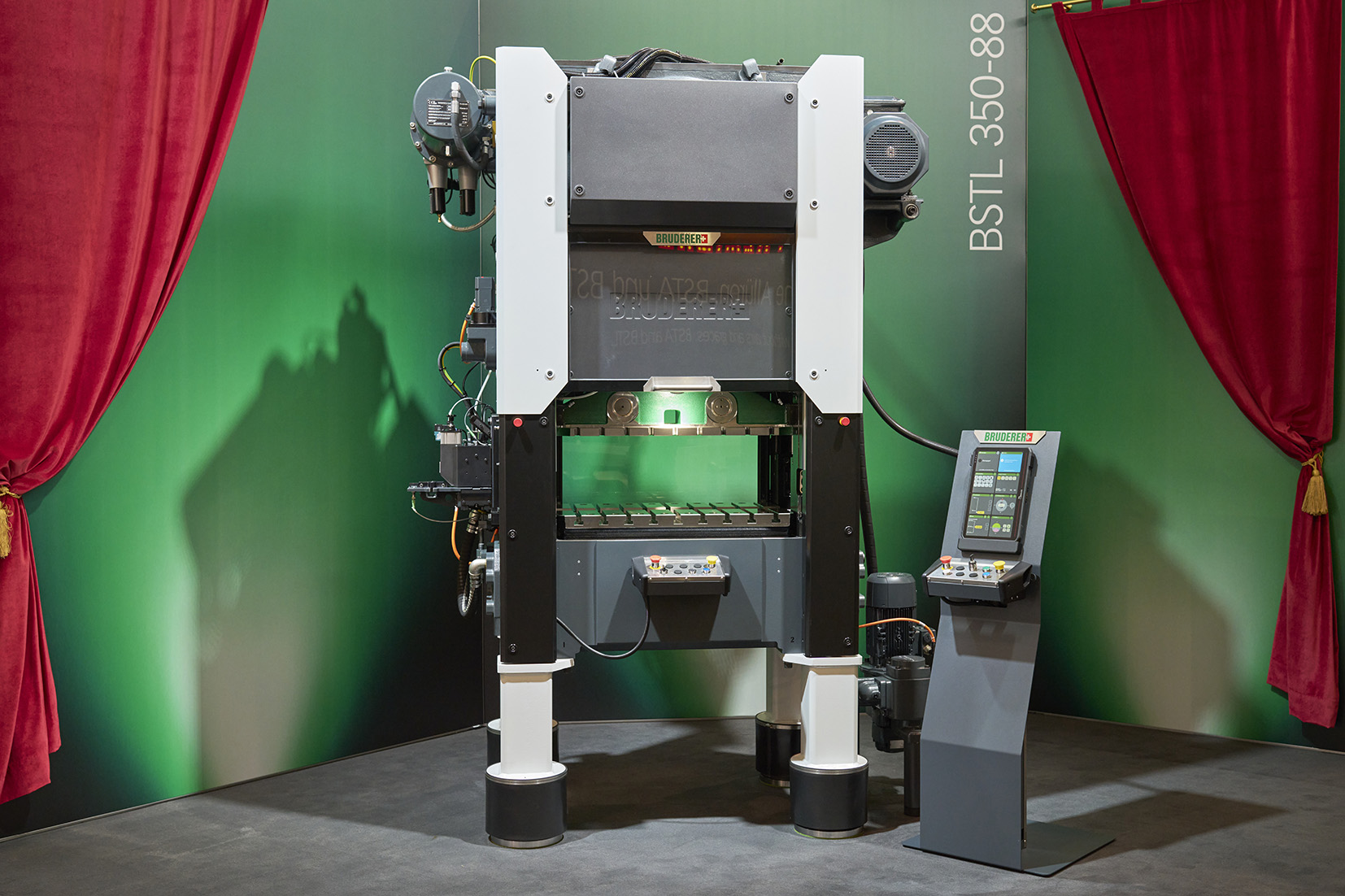

Despite a reluctance to invest on the part of automobile manufacturers, Schuler has been able to book some important orders so far this year Hanover, October 22, 2024 – Like many other companies in the mechanical engineering sector, Schuler [...]