The MMMA Celebrating their 75th Anniversary at MACH 2024, are very excited to announce that there will be over 500 square metres within the Metalworking Village for MACH 2024.

Featuring over 20 member companies, MMMA encourage visitors to make their way to Hall 6 entrance to spend time with members. Visitors to the Metalforming Village will be interested to see a number of leading edge technologies on display. These will include technologies and services from:- Press Form, Midland Power Press, Presscare, Bruderer UK, Schuler Presses, Worcester Presses, Decade Monitoring, Oerlikon Balzers, Group Rhodes, AIDA, TMA Engineering, Industrial Clutch, Press Techniques, Phoenix Tooling Developments, Otto Bihler, Buck Engineering, Formit, Sheetmetal Industries, Kaller Banres Group, Costa levigatrici, GE Machinery, Sigmanest Europe, Faccin Group, Qualimach, OSA Systems, Worcester Presses.With so many working exhibits on display, the MMMA, Metalworking Village looks set to be the best yet for attracting visitors.

TMA Engineering:

“We have been in business for over 50 years and will be exhibiting our range of TMA World Presses, TMA servofeeds and coil feed equipment, along with our breakdown, repair, maintenance and inspection services.”

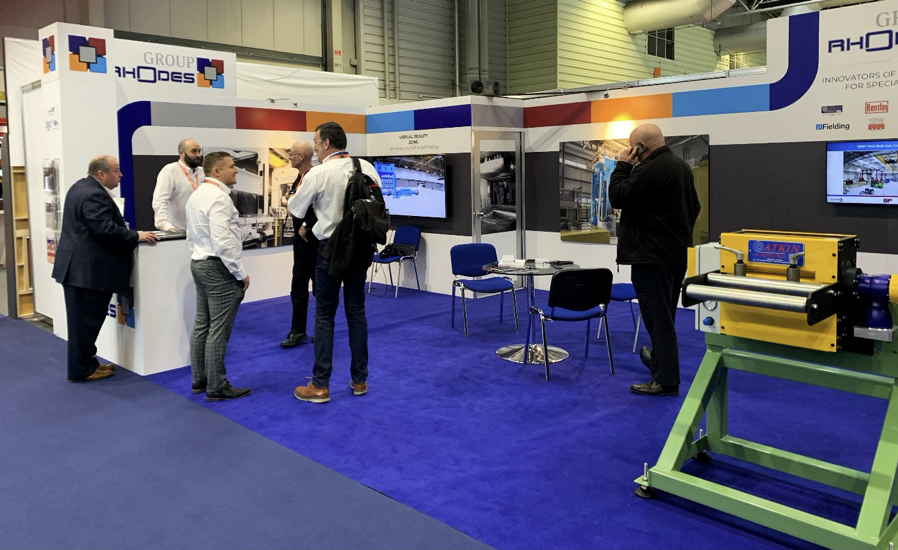

Group Rhodes to Showcase its Bespoke Metalforming Machinery at MACH 2024

Group Rhodes, a leading manufacturer of metal and composite forming machinery, will be demonstrating one of its innovative metalforming presses within the MMMA Metal Working Village at MACH 2024

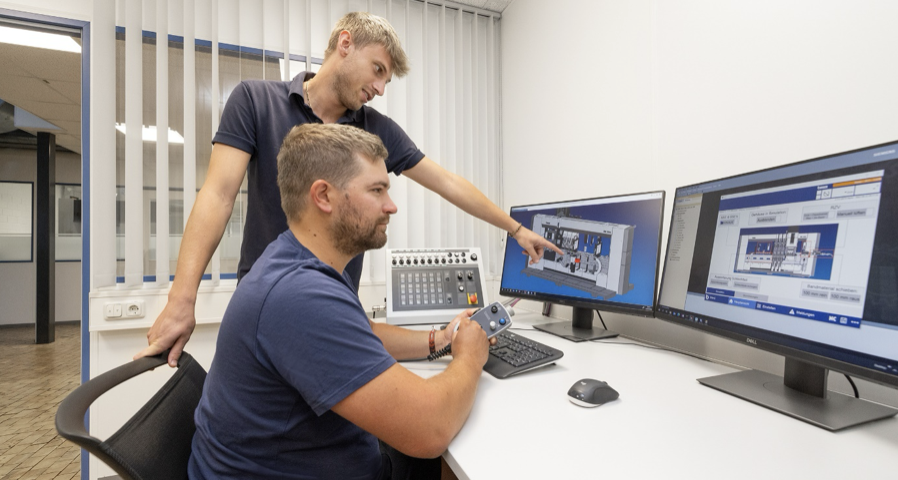

Virtual commissioning of Bihler machines

Otto Bihler Maschinenfabrik creates digital twins of complex manufacturing solutions and commissions the entire system virtually in advance. This allows the machine to be configured optimally, increases

the quality of the software and ensures fast, smooth initial commissioning and optimization of the production system.

Valuable time and quality benefits

To date, Bihler has already commissioned more than 20 highly complex manufacturing solutions virtually. The feasibility of components with a high degree of variability has also been successfully confirmed, including testing for crashes and the sequencing of the positioning axes. In all projects, it became apparent that the simulations enabled all subsequent setup and commissioning times to be reduced by up to 15 percent.

Press-Form:

PRESS FORM With over 30 years’ experience in the supply and servicing of sheet metal working machinery Press-Form is firmly positioned as one of the UK’s leading providers of metal process equipment.

Our extensive expertise within the industry ensures we provide a first class service to our clients. We represent many high profile equipment and system manufacturers from Europe, USA and Canada, and we have an extensive range of production enhancing machinery for sale.

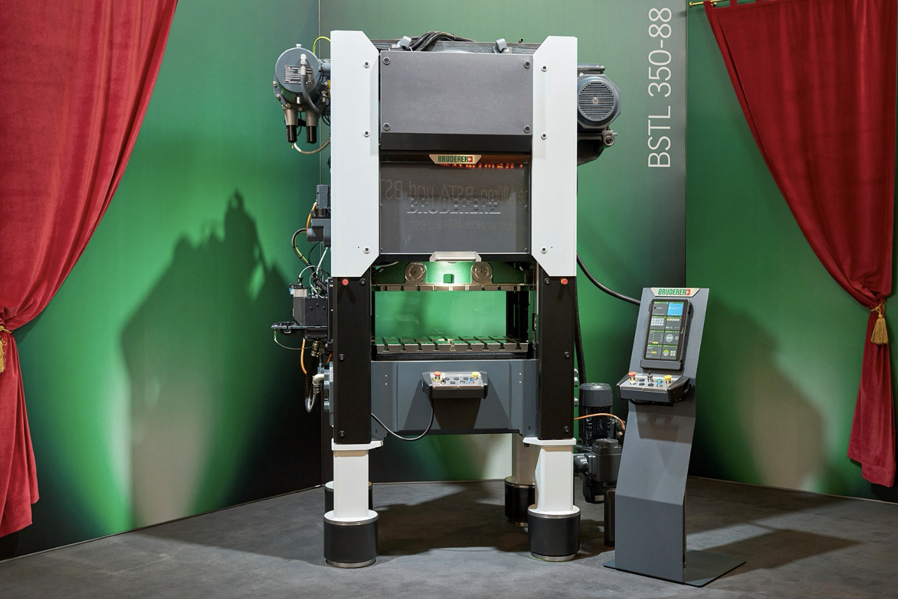

Bruderer UK Ltd

Adrian Haller MD New developments are always a thrill to show, and I am particularly excited about this year’s showcase of cutting-edge technologies, where Bruderer UK is set to unveil as the Exclusive UK Launch our groundbreaking press the BSTL 350-88, at the exhibition operating as a full production line and full details of our New to the UK BSTA 710-220B press.

Worcester Presses Ltd

Worcester Presses Ltd will be exhibiting a Chin Fong OCP-80 ton press along with promoting Tomac Coil Handling equipment, C-Frame and Straight side Hydraulic presses, Quick Die change equipment, load monitoring, and robot/transfer equipment.This year our stand is the largest to date, 32 sqm. We have increased the size of the stand to accommodate more visitors after the success of MACH 2022. Michael Rutters Isle of Man TT bike will also be on the stand.

Pheonix Tooling Developments:

Phoenix Tooling Developments will be exhibiting a range of its press tooling solutions including :

The latest battery & EV tooling solutions that Phoenix Tooling & Development have actively rolled out into full scale production lines, our Multi-slide tooling experience.

High speed progression tooling examples, decorative stamping samples, complex stamping solutions & full turn-key production line capabilities.

Leave A Comment

You must be logged in to post a comment.