Making the location future-proof

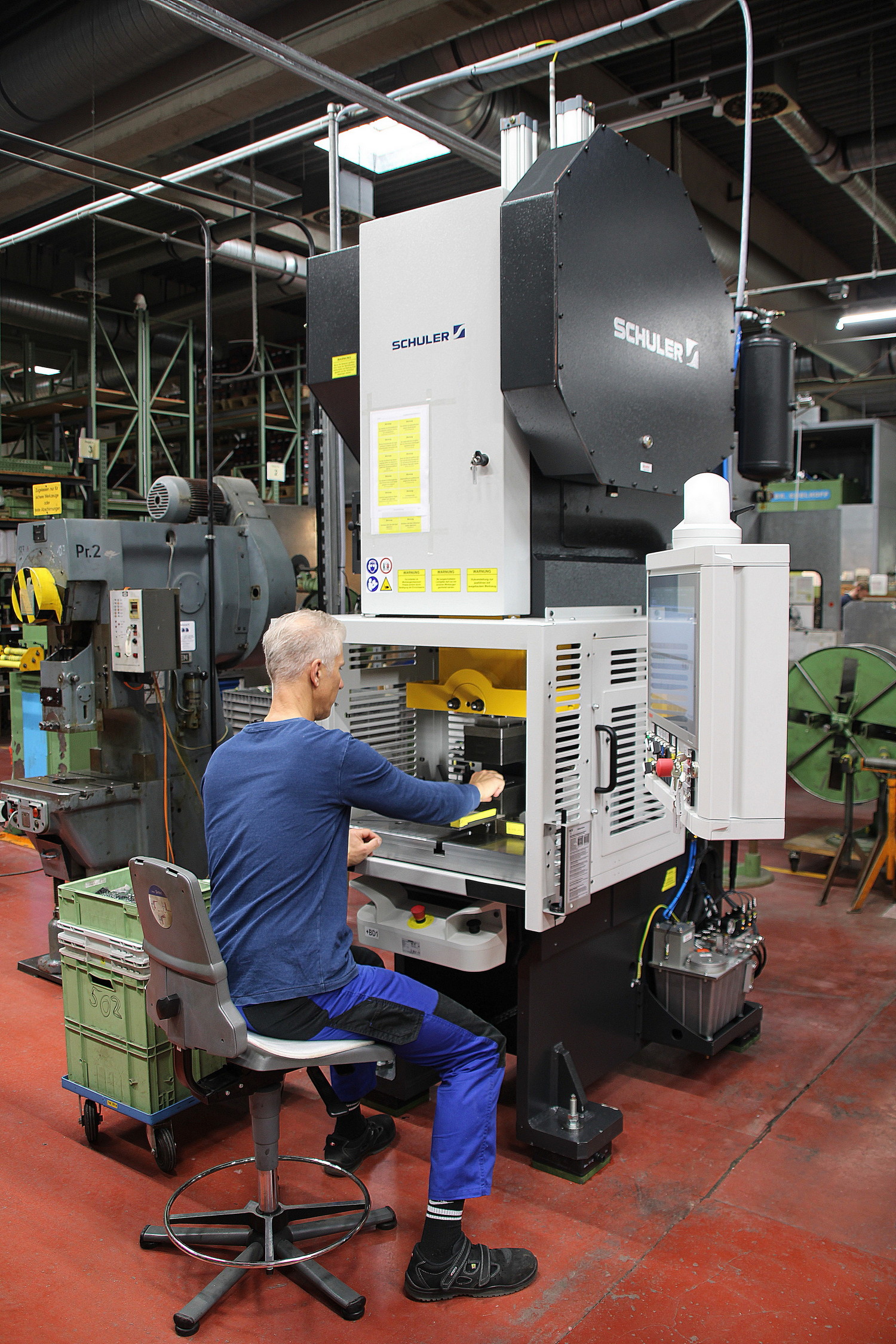

Thuringia's Economics Minister Wolfgang Tiefensee visits Erfurt / Schuler considers selling welding plant and mechanical production facilities. During a visit last week, Thuringia's Minister of Economic Affairs Wolfgang Tiefensee discussed with representatives of the company how Schuler's Erfurt site [...]