We have reached a new milestone. In October 2022, AP&T received an order for its 150th press-hardening line, thereby securing their position as the leading global supplier of press-hardening equipment for the automotive industry. The customer is Liuzhou Saike, subsidiary of one of China’s largest auto manufacturers, SAIC Motor.

Twenty years ago, when AP&T decided to invest in press hardening, it was not easy to predict just how far things could lead. Today, the company is one of the most prominent suppliers of production lines for manufacturing press-hardened components and has auto manufacturers and sub-suppliers from around the world on their list of customers. How did that come about?

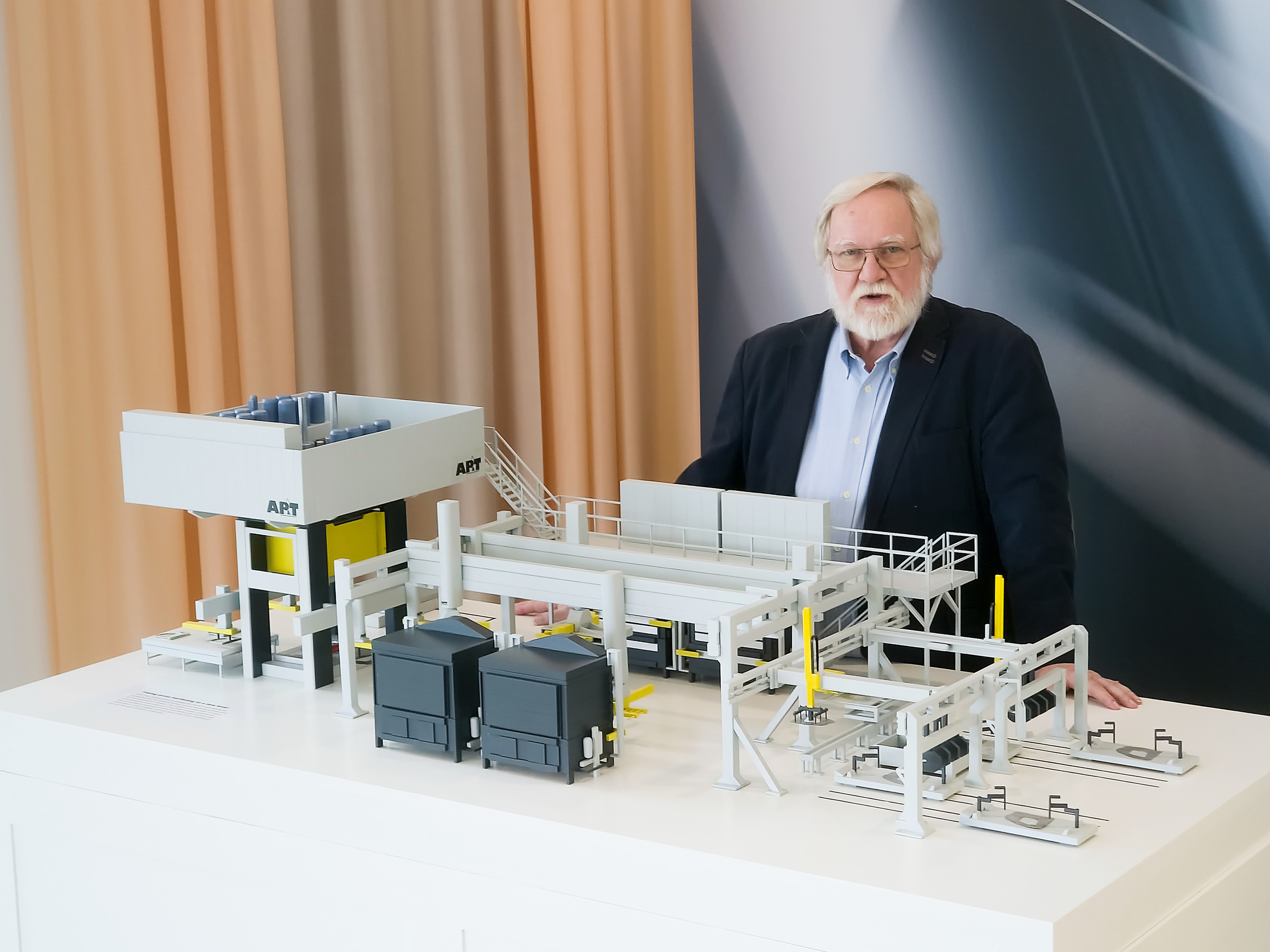

Mats Lindman, a Sales Manager at AP&T who has been on the greater part of the company’s successful press-hardening journey.

Ford Mustang kick start

“In 2002, we were approached about delivering a press and a few linear robots for a line that would be used to press-harden fender components for the Ford Mustang in the US. The collaboration was a successful one and sparked the decision to increase our process expertise. We realized that the area held great potential,” says Mats Lindman, an AP&T Sales Manager who has been on the greater part of the company’s successful press-hardening journey.

In 2004, the company conducted its first major press-hardening deal under the name of AP&T to supply Benteler Automotive in the US with three production lines. The following year, Benteler placed an order for yet another line, this time for its Changchun, China facility.

First line to China

“It was our first delivery of a press-hardening line to China, which would become our single largest market for this type of equipment after just a few years. It’s been 18 years, but the line we installed in 2005 is still in full operation!”

The foundation for continued success in China was laid when Bao Steel, the third largest sheet metal manufacturer in the world, contacted AP&T in 2006. Mats Lindman was also key to that customer relationship.

“They wanted to more deeply explore the opportunities press hardening offers. In order to demo the technology and test-manufacture various components for Bao Steel, we built up a complete line at our facilities. It eventually resulted in orders for several lines for them in China,” he says.

The breakthrough – five lines for Fiat

At this time, demand for AP&T’s press-hardening solutions was also increasing in Europe and the US. A major breakthrough came when Fiat placed an order for five complete production lines for their factory in Cassino, Italy in 2008.

This opened up for deals throughout the world with OEMs and suppliers of car parts and components, causing the automotive industry to grow into one of AP&T’s largest customer categories.

“Parts manufactured with AP&T’s press-hardening equipment are currently used by most major car manufacturers. Aside from the OEMs already mentioned, the list includes Volkswagen, Volvo and Great Wall Motors, who we either have, or have had, direct relationships with through the years. Many first-time deals led to more business,” says Lindman.

150 lines ordered

Press-hardening line number 100 from AP&T was installed in the spring of 2018 at the MA Polska facility in Tychy, southern Poland. And this summer, line number 150 will become operational in Liuzhou Saike’s facility in Liuzhou, China. The parts manufactured here are used in SMGW’s car models, including the best-selling electric vehicle in China, Hongguang MINI EV.

In the 20 years since AP&T’s first step toward press-hardening, the technology has consistently developed and been refined.

Tech development that pushes the boundaries

“With the help of systems for advanced process control, innovations such as TemperBox®, Multi-Layer Furnace and our servohydraulic press, we have pushed the boundaries of what is possible. The technology has created entirely new possibilities for the automotive industry to effectively design and manufacture components with the desired attributes at a higher, more even quality level. This has in turn led to cars that are safer, lighter and have less of an impact on the climate and environment.”

According to Mats Lindman, other AP&T success factors are how the offer is viewed, customer relationships and the method of doing business. This approach falls under the One Responsible Partner® label.

A holistic solution that performs throughout

“As an experienced expert partner, we do not only deliver high quality machines, but also take responsibility for a turnkey, needs-adapted holistic solution with high lifetime performance.”

Just as the technology has continuously developed through the years, so has AP&T’s service offering. In addition to the service, maintenance, repairs, spare parts and training offered today, the company also offers optimization and upgrades of existing machines, which is often a very lucrative measure for customers. AP&T also offers various forms of availability agreements that are tailored to the customer.

“In the future, I believe that there will be a considerable increase in customers who choose contract-based solutions, meaning we will take a more extensive, longer term responsibility. For instance, we already have a performance-based agreement in which you choose to pay a certain amount per press cycle rather than purchase equipment the traditional way. Each new deal marks the start of a journey, and our goal is to make it as easy, profitable, secure and problem-free as we can for each customer.”

So how is the future of press hardening looking?

“During the pandemic, demand leveled out for a while, but now the arrows are pointing up again, not only for upgrades of existing machines, but also for new sales. So yes, press hardening absolutely has a future,” says Lindman.

Read more about AP&T’s total press hardening solution offering at https://aptgroup.com/solutions/automotive/press-hardening

Leave A Comment

You must be logged in to post a comment.