“Our furnace systems meet the growing needs of solutions for the automotive industry that will make production more efficient and make vehicles lighter, safer and more energy-efficient. We are now dedicating AP&T furnaces its own business area, increasing the potential of developing future solutions with our customers,” says Pär Mickos, Product Manager of Furnace Systems at AP&T.

AP&T, with headquarters in Ulricehamn, Sweden, develops and manufactures steel and fiber-forming production solutions. Its largest customer segment is in the automotive industry. The company is a world leader in press hardening of sheet metal and has repeatedly received recognition for its process technology for hot forming high-strength aluminum. They have developed and manufactured multi-layer furnaces since 2010.

“In terms of volume, we are already one of Sweden’s largest manufacturers of furnaces for industrial applications. We have a well-proven program of competitive products and considering the growth potential we see in our niches on the global market, we are ready to expand,” says Pär Mickos.

Designating a business area to furnaces at AP&T, in similarity to those for presses and automation, means an increase in customer focus and resources for e.g., product development.

Energy-efficient, electric Multi-Layer Furnace

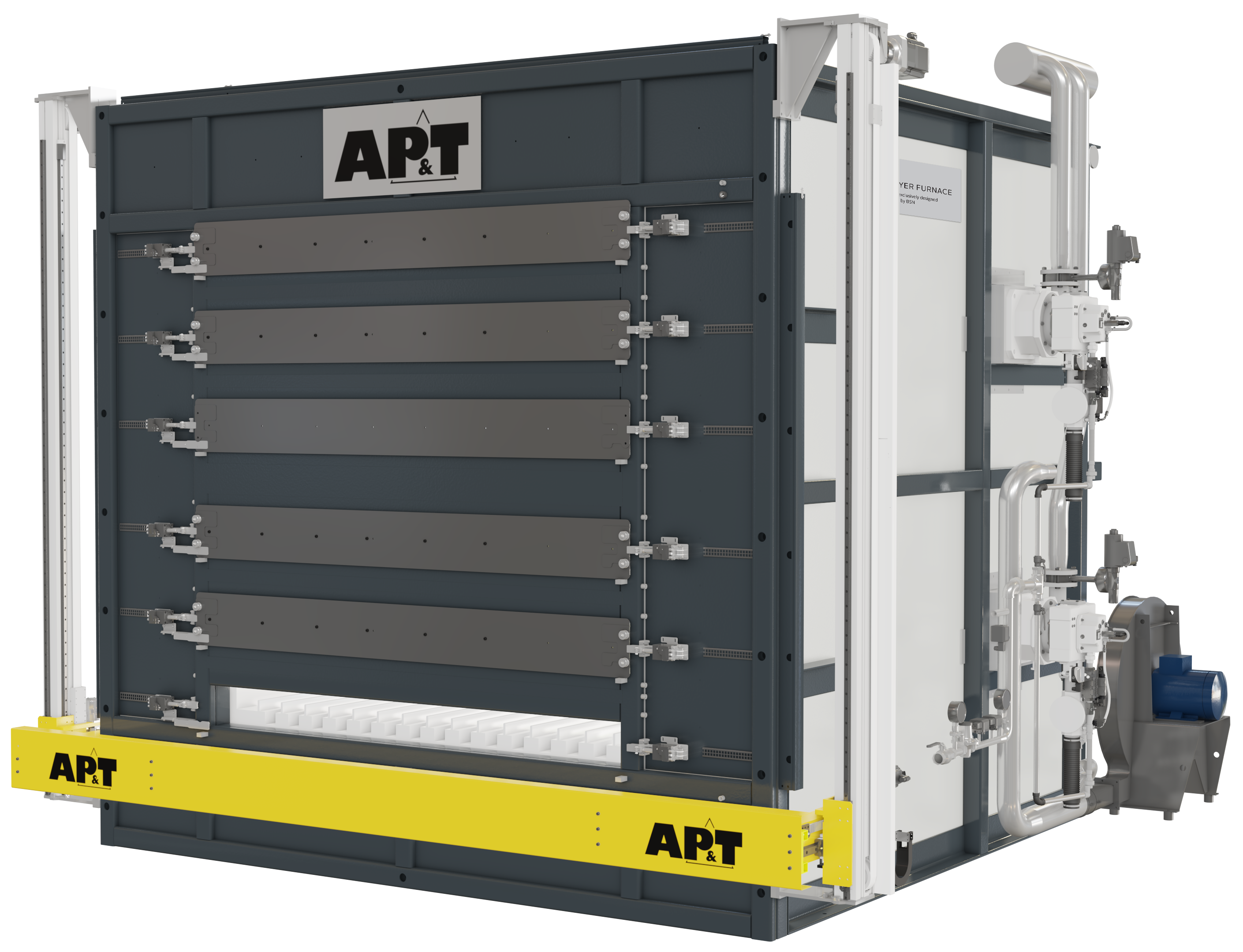

The foundation of the current product program is AP&T’s energy-efficient, electric Multi-Layer Furnace, available in a number of designs for press hardening and hot forming aluminum. Its multi-layer design means it has a relatively small footprint on the shop floor than conventional roller hearth furnaces. It has few moving parts which reduces the need for maintenance and production can continue, even if one of the furnace layers needs to be shut down. All furnaces are equipped with AP&T’s feeding and unloading automation.

AP&T’s energy-efficient, electric Multi-Layer Furnace is available in a number of designs for press hardening and hot forming aluminum.

In addition to the Multi-Layer Furnace, the press hardening furnace program includes advanced systems for process monitoring. Also included is AP&T’s patented solution for partial hardening, TemperBox®, which makes it possible to combine soft and hard sections in one and the same component.

The Multi-Layer Furnace is part of AP&T’s solution for hot forming high-strength aluminum, as are AP&T’s servohydraulic press and automation. The process makes it possible to manufacture complexly formed components in demanding aluminum alloys, effectively and with short cycle times.

All furnace products are also included in AP&T’s aftermarket offer which will not also include e.g., new types of availability agreements.

“As a long-term partner to the global automotive industry, we will continue to be forerunners that offer products and services that help customer companies take a step into the future. Here, our furnace system will be an important part of our total offering,” says Mickos.

“We are now dedicating AP&T furnaces its own business area, increasing the potential of developing future solutions with our customers,” says Pär Mickos, Product Manager of Furnace Systems at AP&T.

Leave A Comment

You must be logged in to post a comment.