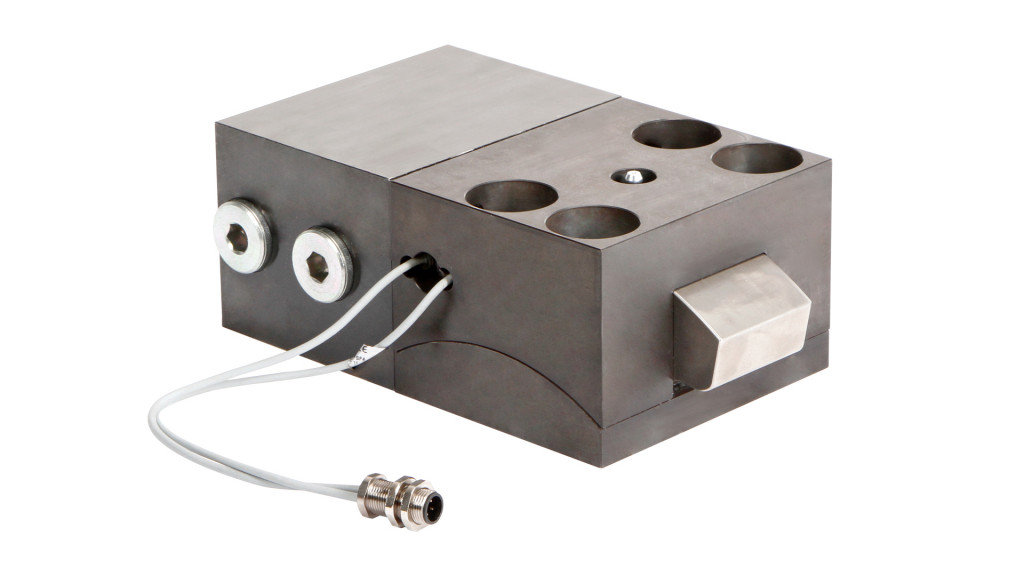

A new range of seven double-acting arch clamps has been introduced by Roemheld for securing dies or moulds to the bed or ram of a die casting, injection moulding or other type of press. Intended for holding tools with flat edges safely, the compact clamps exert a force ranging from 30 to 450 kN.

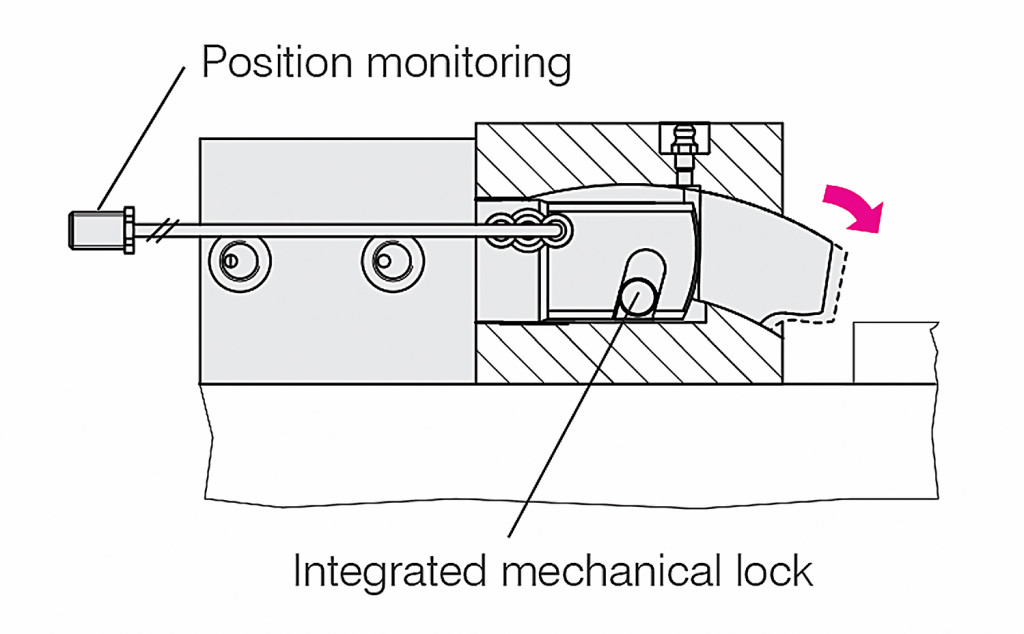

They consist of a hydraulic block cylinder and piston. Due to the internal design, the horizontally-acting force is translated into an almost vertical clamping action. An integrated mechanical locking bolt is provided to maintain the clamps in position, particularly on the ram, in the event of a drop in hydraulic pressure.

Supplied without or with position monitoring, the former clamps may be used at temperatures up to 160°C (300°C on request), while the latter may be used up to 100°C. The integrated position monitoring at the side is coupled to the clamping bolt and signals either unclamped or clamped status or clamping position overrun error. Special versions are available that provide a continuous signal up to the final bolt position.

The arch clamps feature sturdy construction as well as corrosion resistance due to the application of a special coating. They are intended for use with location pins or limit stops to keep the mould or die in its correct position, as during use it is subjected to side loads that, although low, may be strong enough to cause displacement.

Pics:

1. One of the new arch clamps from Roemheld.

2. A schematic of an arch clamp showing the locations of the position monitoring and integrated mechanical lock.

Leave A Comment

You must be logged in to post a comment.