The market for Electric Vehicles has grown exponentially since 2013, and is expected to continue growing at a fast rate.

According to the International Energy Agency (IEA), the number of Electric Vehicles in use in the world has grown from about 380,000 vehicles in 2013 to nearly ten times as much in 2017, with over three million Electric Vehicles on the roads (see report).

The latest developments in the underlying technology, and the attractiveness of government incentives like subsidies and exemptions from parking fees in some countries, adds to the popularity of Electric Vehicles. Most vehicle manufacturers are by now developing and releasing an offering of Electric Vehicles and/or hybrids alongside combustion engine vehicle models to answer to market demand.

An Electric Vehicle that is plugged into a power source to charge the batteries frequently requires an addition to the manufacturing process of the vehicle body. For vehicle manufacturers this means that new requirements, in the form of e.g. fender variants for a vehicle body, need to be handled in the production process and the design of tools and die.

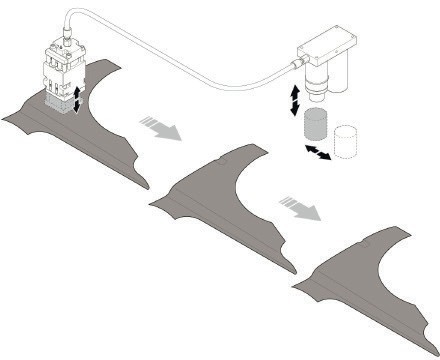

For a new vehicle model, manufacturers can set up the new production process to include an EV charge port for Electric models but eliminate the port for other models – all in the same die. Using advanced, cost-effective cutting tools that can be positioned at a 360° angle and perform multiple operations in a die, a vehicle manufacturer can reduce the amount of steps and tools required for producing a fender with, or without, an EV charge port.

To read the full report click here: https://www.kaller.com/en-us/kaller-case-studies/case-studies/case-1-flex-cam-for-ev-fender/

Leave A Comment

You must be logged in to post a comment.