German press brake tooling and guillotine shear blade manufacturer, UKB Uwe Krumm GmbH, Burbach, whose products range from 60 mm to 6,000 mm in length and weigh from a few hundred grams to several tonnes, has 14 machining centres on its shop floor. Across all of the equipment, which is also employed for general subcontract machining, only two types of vice are used regardless of the size and geometry of the component and the material being processed.

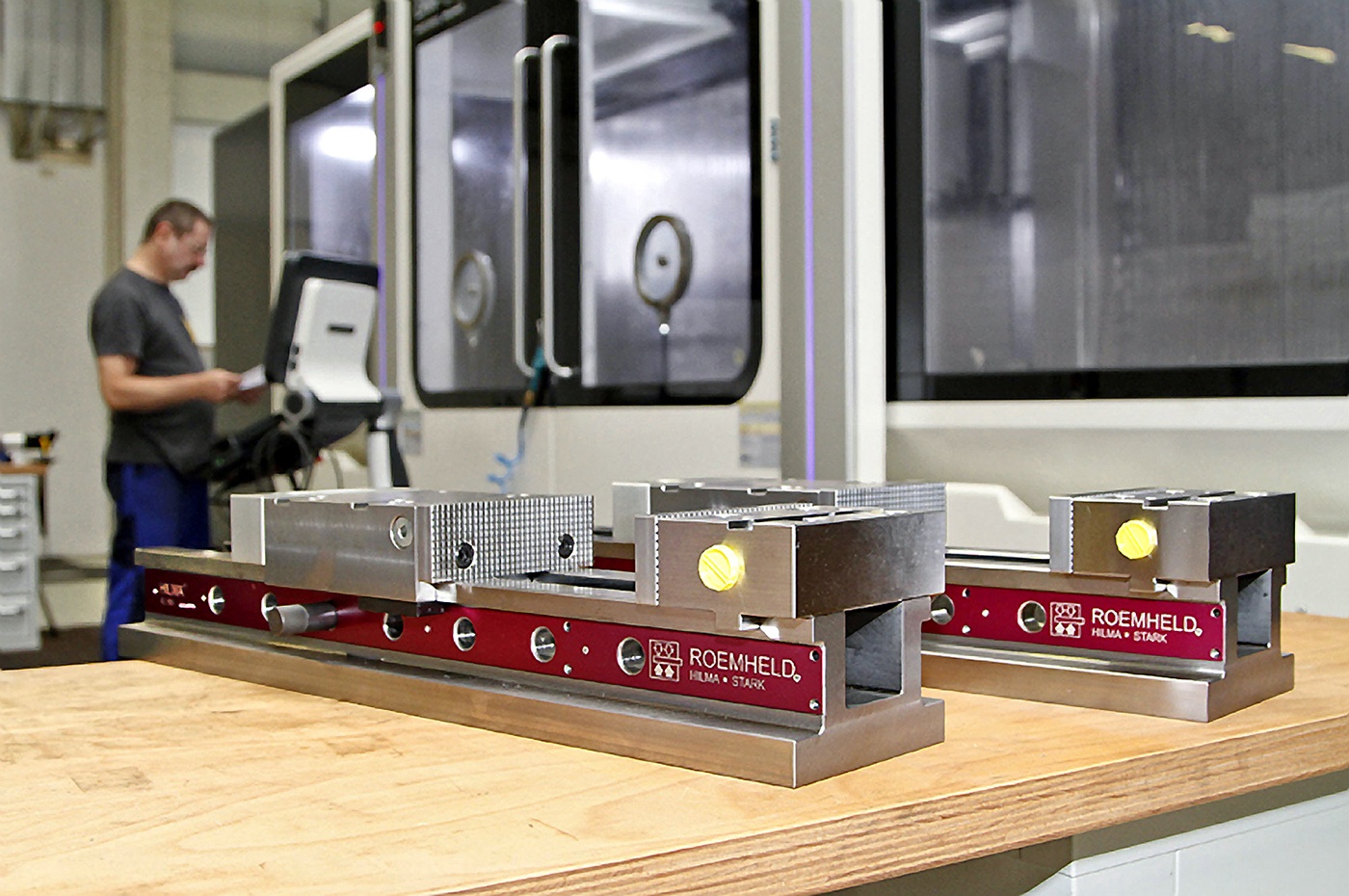

The workholding devices are supplied exclusively by the Hilma division of the Roemheld group, whose factory is in nearby Hilchenbach. There are around 90 vices in use from the firm’s NC160 and VL160 series. Supply of these products in the UK and Ireland is through subsidiary company Roemheld UK, Hitchin.

Standard base length of the vices is 750 mm, providing a clamping range of 508 mm, sufficient for most of UKB’s workpieces, while various top jaws enlarge the range to a maximum of 772 mm. Configurations vary from five vices on the smaller milling machines in Burbach up to 14 vices on a DMG Mori DMF 600 linear 5-axis model with a six-metre X-axis.

UKB’s head of production Peter Diehl said, “We use the vices for everything from simple 3-axis operations to complex, 5-axis machining applications requiring multiple set-ups. They are highly precise, always dependable and easy to use.”

In view of the requirement for high precision machining, typically to within ± 0.01 mm, Mr Diehl attaches special importance to process reliability.

He added, “Clamping components with minimum deformation is of major importance to us. With Hilma machine vices, we can hold the workpiece at maximum pressure for roughing – say to reduce a tough Hardox steel blank for a 5-metre tool weighing six tonnes to just 1.5 tonnes – then lower the clamping force for finish machining.”

The workholding systems, which are either manually operated or hydraulically actuated by hand or a foot switch, are mounted in either a horizontal or vertical orientation. They can be configured in numerous ways for optimum flexibility to simplify process routes and are quickly and easily adapted to suit different workpieces. Mr Diehl advised that the vices and the on-site service provided by Hilma are very reliable, reducing machine downtime to a minimum.

Leave A Comment

You must be logged in to post a comment.