MA’s headquarters are in Rivoli, Turin, Italy, and the company has been a large manufacturer of cold-formed sheet metal parts for the global automotive industry since the 1970s. A few years ago the company decided to begin manufacturing press hardened components as well, which thank

The press hardening line, which was deployed in spring 2018 at MA Polska’s facility in Poland, was the hundredth press hardening line that AP&T has installed over time. From left, Sergio Costamagna, MA Polska, Lennart Johansson, AP&T, Alessandro Salvi, MA, and Sławomir Grabowski, AP&T.

s to the combination of low weight and high strength are increasingly being selected for use in modern passenger cars.

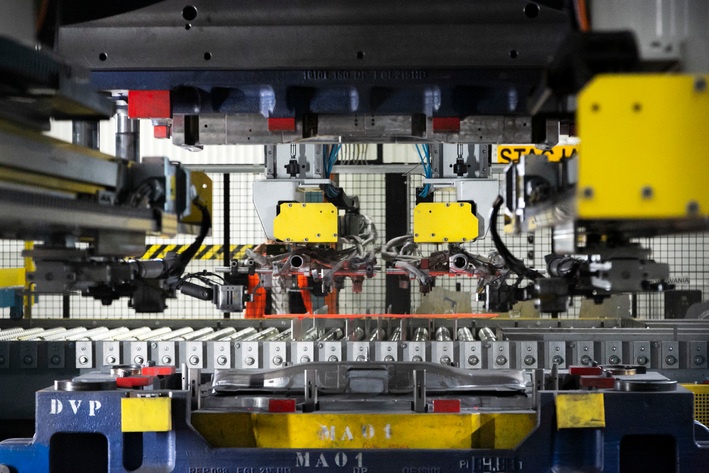

AP&T, which has worked with press hardening since the beginning of the 2000s, was entrusted with supplying an ultra-modern press hardening line to MA Polska’s facility in Tychy, in southern Poland.

The line was deployed in spring 2018. Not only was it the first of its kind for MA, it was also the hundredth press hardening line that AP&T had installed at that point. In other words, the installation was a milestone for both companies.

The new line is a complete, turnkey state-of-the-art solution. It is equipped with AP&T’s unique system for in-line process monitoring, which means parts can be manufactured with a consistently high level of quality in a carefully controlled process with short cycle times. As a result, the car industry’s CQI9 quality standard can also be effectively fulfilled.

“MA understood the opportunities afforded by our technology early on, which has made cooperation very invigorating. It is always especially gratifying when both parties aim high and are able to reach common goals,” says AP&T Product Manager Line Lennart Johansson.

MA is also very happy with how cooperation has developed.

“We are very satisfied with the challenging and productive cooperation we have had up to now. We are confident we will continue along the same path in the future, as we are aware that this technology is becoming more and more strategic in the automotive industry,” says Jean Lamontanara, responsible for R&D and Material Management at MA.

Facts

AP&T’s in-line process monitoring system

Enables an optimized and well-controlled press hardening process. Pyrometer and infrared camera technologies are used to measure the material’s temperature with a high degree of precision both before and after pressing.

The MA company

MA is the metal automotive components division of the CLN Group.

Specializes in producing and assembling metal automotive structural parts, components, subassemblies and modules.

Presence in Italy, rest of Europe, South America, Africa and Asia. Manages 26 production plants and 3 research and development centers.

- The process enables compliance with the car industry’s requirements as specified in the CQI9 standard.

- MA Polska’s press hardening line is a complete, turnkey solution, equipped with AP&T’s unique system for in-line process monitoring.

Leave A Comment

You must be logged in to post a comment.