This month our member spotlight turns to Helm Instrument; the leading designer and manufacturer of process control systems, force transducers and software for the metal forming industries.

We sat down with Ian Pell, Managing Director, to find out more.

Can you tell us about the history of Helm Instrument?

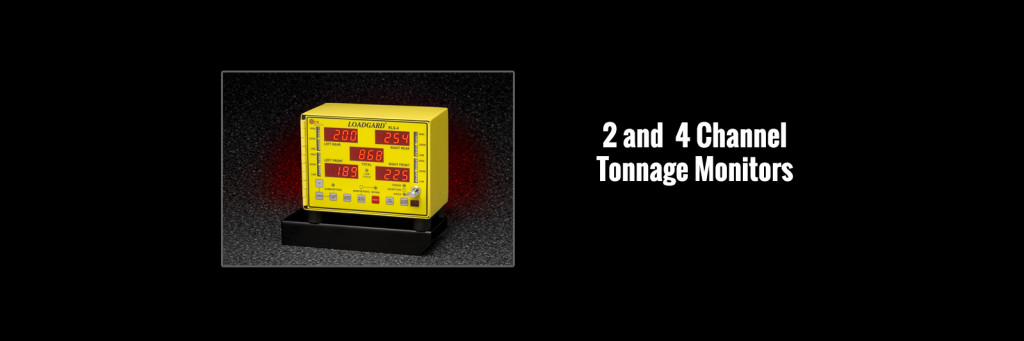

The company was founded by Donald F Wilhelm in 1962, Ohio, USA. Helm Instrument has grown to be a world leader in the design, manufacture and innovation of tonnage and control systems. In 1968, Helm introduced its first 2 and 4 channel tonnage monitors for the stamping industry. Today, the product line also includes machine controls, plantwide networking software with SPC. Charting Industries served to include stamping, forging, die-cast, injection molding, thermoforming and pharmaceuticals.

How have the last 12 months been for Helm Instrument?

The last 12 months for Helm have been mixed, yet extremely successful. Specifically, within the automotive industry with large projects including Nissan & Renault (Globally), GM and Chrysler. We also supply extensively into 2nd and 3rd tier suppliers within the automotive trade, who have maintained an element of continued manufacturing. Over the last four months, business has slowed down, owed to the Coronavirus pandemic, which directly affected travel and export. Although, sales and service within the USA were less-affected mostly due to the demographics with equipment and products used diversely across other industries, such as the pharmaceutical industry who ramped-up their manufacturing. Weigh-scale instrumentation and specially developed modules for the Allen Bradley plc platform was key to ‘filling-in’ gaps in supply.

What is something not many people know about Helm Instrument?

Helm Instrument is well known internationally for its expertise in tonnage measurement in the stamping industry. As a company, we also design and manufacture machine control systems for a wide array of industries. We also have specialised in the power press industry, of which many have been sold here in the UK. Products are sustained worldwide with global agencies in many key geographical locations. We supply all our products in the UK and Europe directly from the UK. Our UK based R&D and manufacturing facilities are in the North of England with technical support nationwide. With our extensive engineering experiences in many disciplines, we offer services such as machine performance, automation and safety consultancy. Helm is also a global partner with Rockwell on their Encompass program and has license agreements with Estun a major manufacturer of control systems in China and Riken, based in Japan. We also manufacture tonnage and weigh scale modules for communication through any PLC and license agreement with Rockwell. We manufacture modules that sit directly on the backplane of all the Allen-Bradley range of PLC platforms. Helm load cell modules are used on many applications including; packaging, filling, batching and weighing.

What would you like to see from the company in 2021?

Over the last 58 years, Helm has continually brought new innovations to the industry such as Auto Zero and Signature Analysis. I would like to see us carry on this history and continue to grow through new developments and improve our position in the marketplace.

We would also benefit hugely from improved visibility in the marketplace, stronger advertising and marketing. Our web presence is currently under review and we will be instigating changes to assist customers searching for the services we can provide. Word-of-mouth has served us well over the years and still does, but we need to acquire search results with successful hits.

What would you say is Helm Instrument USP?

The American ‘customer service’ attitude and approach is well known and revered. Helm continues to extend this methodology with our UK and European customers. Requirements can change rapidly, and we can evolve with them. Products are consistently updated to fit the requirements of customer needs with the ability to redesign a product from the ground-up to cater to individual demand. We have many flexible options at our disposal to provide an amicable solution. Having a highly-skilled workforce with complex core skills who understand the industries that we operate in is imperative to our success. We also have the flexibility and drive within the company to achieve the above.

What are your company values?

We have strong and resilient customer support with minimal time restraints, our aim is to gain as much respect as we provide. Valuing every enquiry we get, no matter of its size or complexity, we pride ourselves on customer support and consideration.

Why did Helm Instrument become a member of the MMMA?

It goes without saying that any tech industry is stronger with diverse connections and networking abilities. Being part of an organisation where members can benefit from extra support or guidance is a huge benefit. We started exhibiting at MACH 2018, but due to time restraints, we missed the time slot to reap the benefits of the membership. We want to participate in future MACH exhibitions, along with other tradeshow events that the MMMA sponsors. Meeting other members of the MMMA to share technologies will also benefit ourselves and our customers. The MMMA could also benefit from our own knowledge and work experiences to help the community grow stronger. Networking is vital.

Finally, how has the Covid-19 pandemic affected your business?

With travel and business coming to a standstill during the pandemic, we have seen a significant drop in business. We hope to participate in the future MACH2022 exhibition and hope that this will give the manufacturing and engineering industries the helping hand that they most desperately need in order for the countries recovery.

Leave A Comment

You must be logged in to post a comment.