Systems for quick and safe changing of heavy tools will be unveiled by the Roemheld Group at Euroblech 2018. Four different configurations of transport cart, which are used to manoeuvre large loads such as heavy moulds and dies ergonomically, will be presented alongside carrying consoles that facilitate insertion into a press. In evidence also will be ball bars and roller bars that allow dies to be smoothly guided and positioned over tables and other surfaces.

Serving further to minimise set-up times in metalforming are Roemheld’s extensive range of cost-effective die clamping and die changing products as well as hydraulic, mechanical, electromechanical and magnetic clamping elements. Systems can be configured for efficient die handling using a combination of new wedge clamps and the appropriate hydraulic supply.

Easy transportation of heavy dies is achieved with the Roemheld RW changing cart for die weights up to 500 kg (left) or 1,000 kg (centre) and the RWA cart (right) for loads of up to 1,600 kg.

Changing carts

Dies weighing in excess of 1.5 tonnes can be manoeuvred with the changing carts. The models exhibited will be the manually operated RW series designed to carry loads up to 500 kg or 1,000 kg, and the electrically-driven RWA cart for a maximum load of 1,600 kg.

All versions feature extensive safety equipment including an automatic docking station with slip protection. With the cart connected to the station, dies can be effortlessly guided and positioned on the changing table via ball inserts, which are lowered during docking to prevent slipping. Height of the changing table can be adjusted hydraulically.

An optional auxiliary drive is available for the manual carts, allowing a travel speed of 2 km/h. Speed of the RWA cart for heavier dies can be steplessly adjusted up to a maximum of 5 km/h. Powerful and durable batteries supply the power.

Carrying consoles

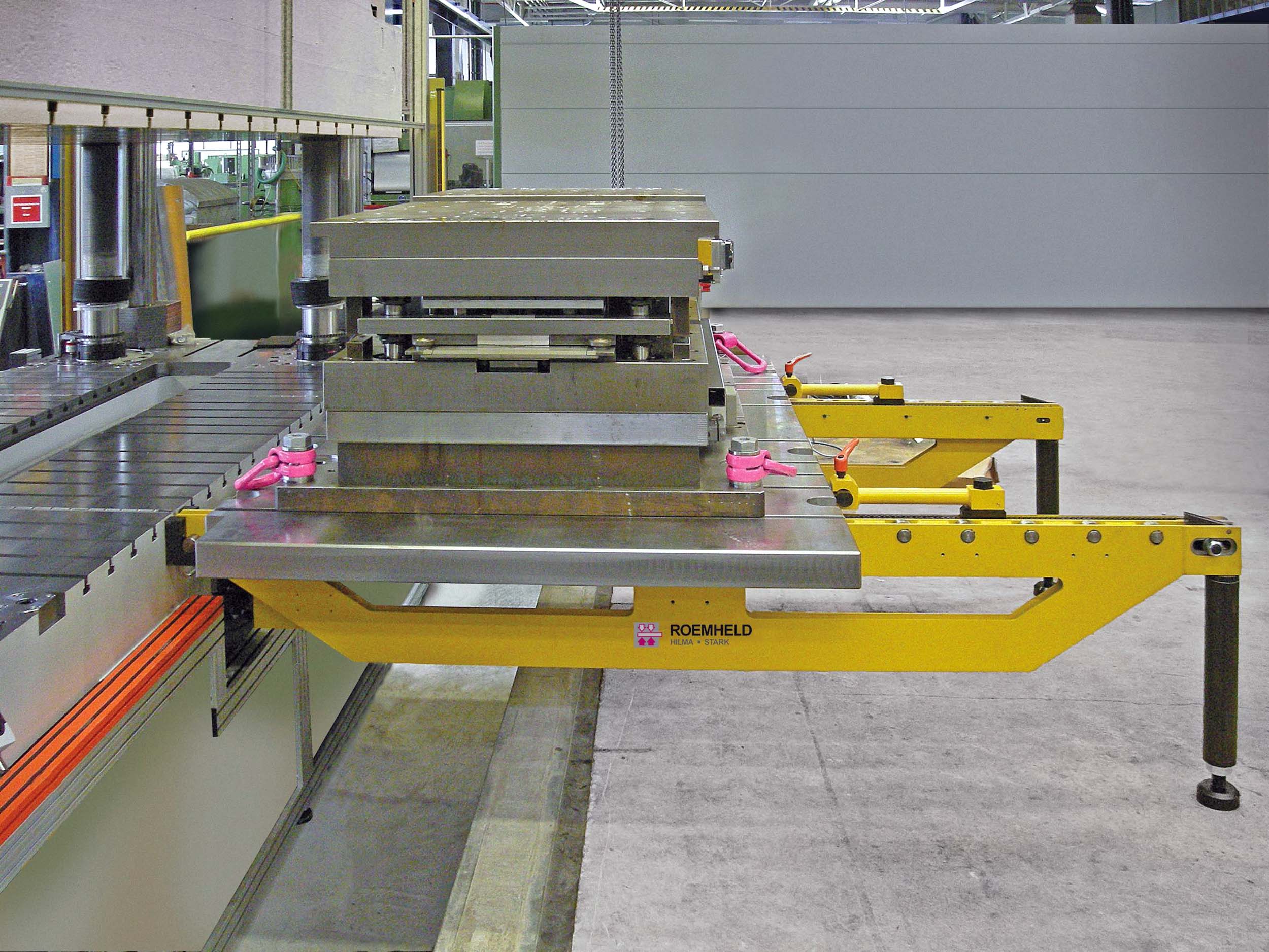

Heavy dies that have been transported by crane or forklift truck can be manoeuvred quickly onto the press table with Roemheld carrying consoles. The dies are placed onto the consoles and from there inserted via integrated transport bars. Versions with or without drive are available, depending on die weight.

Carrying consoles with support feet and drive are suitable for loads up to 32 tonnes.

Attachable carrying consoles that can be suspended from hooks are available for loads up to 250 kN, allowing versatility of use and easy retrofitting. Swivelling consoles for loads up to 60 kN are recommended if space is restricted in front of the press. They are fixed securely onto the press table and can be folded flat against it when not in use.

Versions with additional electric drive and support feet are available for die weights up to 32 tonnes, further increasing versatility and stability. The height can be adjusted by ± 60 mm to compensate for any unevenness of the floor. An automated changing station is included to manoeuvre the new die onto the press table in a linear motion and push the existing die out of the machine to the rear, shortening set-up times further.

Online configurator

Promoted also at Euroblech will be Roemheld’s new, online configurator for simplifying the process of ordering roller and ball bars and ensuring short delivery times. Accessible via the company’s website at www.roemheld-gruppe.de/productconfigurator/?lang=en, it is optimised for use on smartphones and tablets and an app is being developed for Android and Apple devices.

Leave A Comment

You must be logged in to post a comment.