- ROEMHELD: Variety of Carrying Consoles for Quick Die Exchange on Presses

- Reduced Delivery Terms for Driven and Undriven Consoles

- All-in-One Solutions for the Forming Industry

Hilchenbach, 19 February 2019. If large and heavy dies have to be exchanged on presses, carrying consoles are useful and comfortable handling aids. With a comprehensive range and reduced delivery times, ROEMHELD initiates a product campaign. Production process optimisation allowed the Group to reduce the manufacturing time to four weeks.

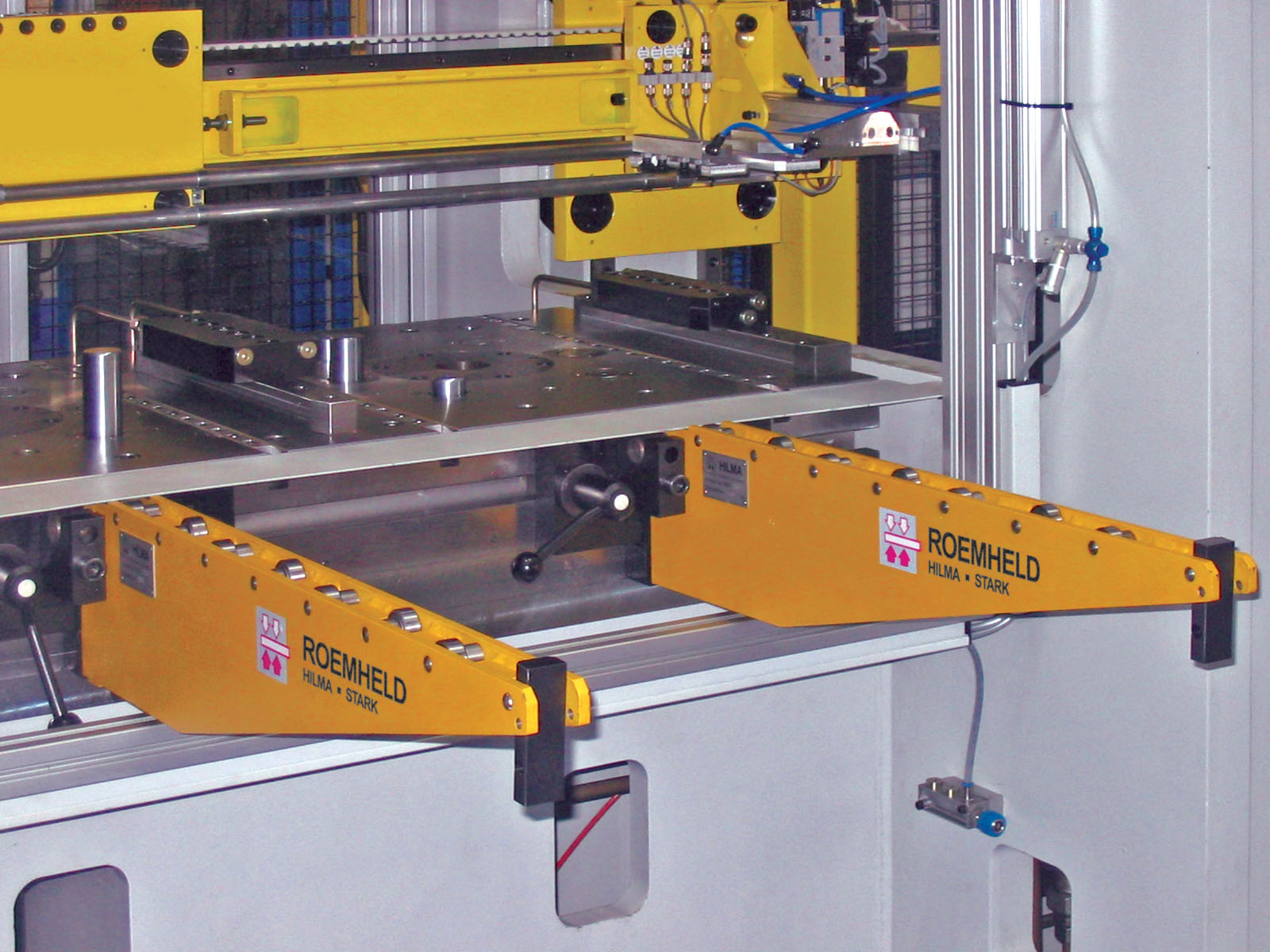

Suspended, displaceable carrying consoles

The carrying consoles facilitate the positioning of dies placed on the consoles by means of cranes or fork-lift trucks. A variety of models is available. The program comprises supported versions, driven and undriven, for carrying capacities of up to 25 tons, suspended and swivelling variants for narrow spaces, as well as an automatable change station for dies with a total weight of up to 32 tons.

This station positions the new die onto the press bench in a linear movement, whereby the previous die is pushed out at the same time. The quick changing process and comfortable handling contribute to setup times significantly with high die weights.

Special designs cover broad application range

In addition, ROEMHELD implements customer-specific versions, e.g. for very high loads, with individual supporting lengths or as displaceable variants. These special designs can be provided with enormous flexibility and adapted to any application in production.

The ROEMHELD Group offers roller and ball bars matching the carrying consoles and used to roll the dies onto the press bench easily. A number of transport carriages for medium to heavy loads supplement the die change technology range.

Carrying capacities of up to 250 kN

Mountable carrying consoles are suspended in pairs in separately fixed receiving hooks on the press change side. This allows for rapid dismantling and use on other machines. They are equally suitable for initial fitting and upgrading, and may significantly reduce the time and effort required for die exchange.

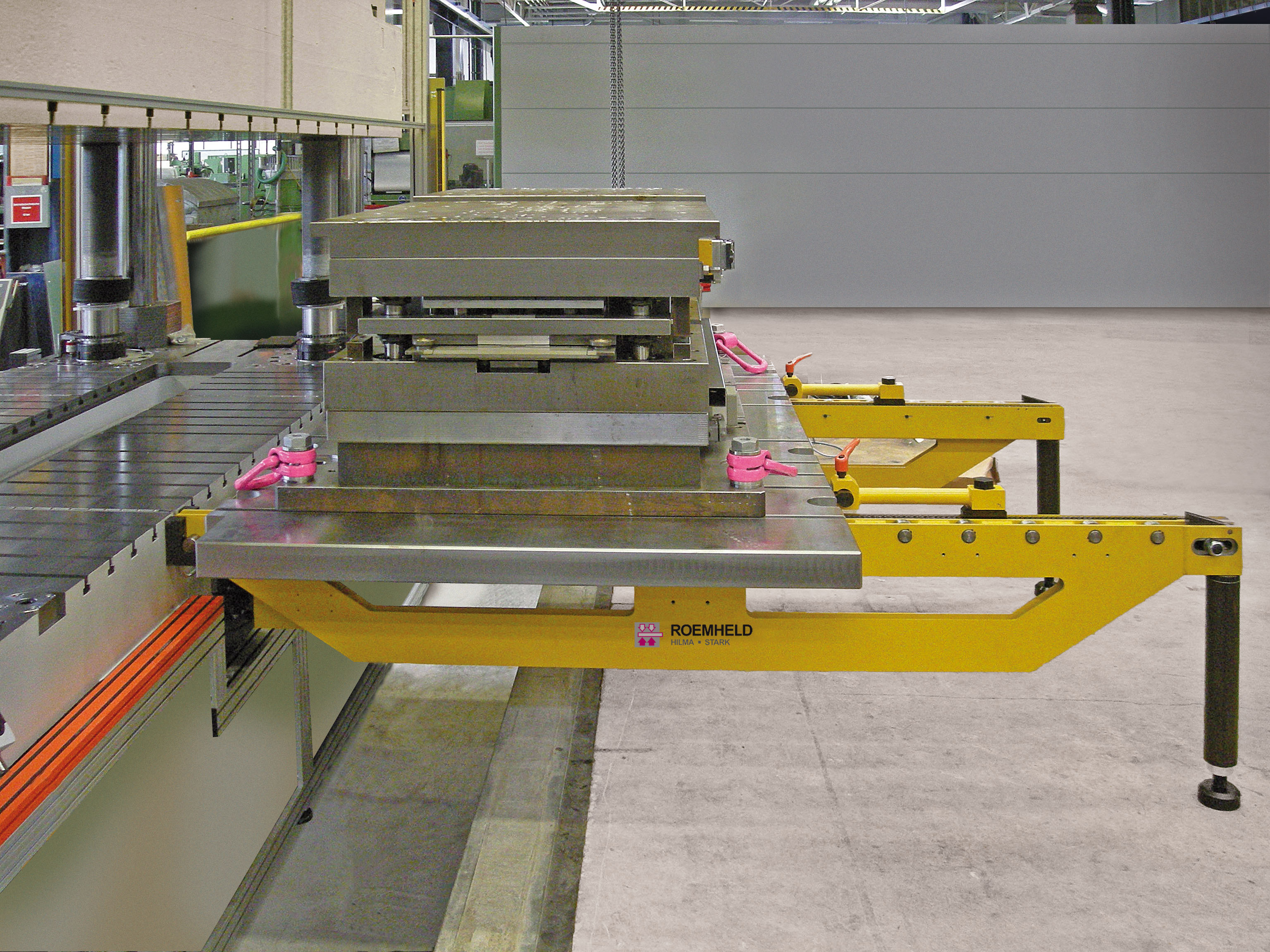

Die change console with supporting legs and drive unit

The die slides into the press via high-strength, hardened needle ball bearings, even with drive support if required. An impact-resistant coating contributes to the ruggedness of the consoles. Carrying capacities of up to 250 kN are covered by the standards product portfolio; supporting length from 500 to 3,500 mm are possible.

Swivelling consoles for narrow spaces

If there is only little space available in front of the press and frequent dismantling is not desired, swivelling models may be used. In contrast to other types, they are permanently fixed on the press bench and can be folded to the bench edge if required. The maximum possible carrying capacity amounts to 60 kN.

Supporting leg and electrical drive unit for dies with weights of up to 25 t

For weights of up to 25 t or large die widths, supporting legs provide for additional console stability. They can be adjusted in height by ± 60 mm so that floor unevenness may be compensated for easily. Positioning is facilitated by an additional electrical drive unit. An cost-efficient option is the combination of crank handle and transmission gear. It can be used for die weight of up to 6 t.

Automation is possible

If an additional electrical pull and thrust drive unit is selected, die placement and positioning can also be automated. The console is combined with roller or ball bars in the bench, and an appropriate inclusion in the press control is provided for.

Complete solutions for die exchange

ROEMHELD also implements all-in-one solutions for clamping and changing dies on the press bench. In this regard, the Group may draw on a comprehensive range of hydraulic clamping devices and modular hydraulic power units.

ROEMHELD: Setup time optimiser for plate forming, plastics and rubber processing

With its extensive range of clamping technology, the ROEMHELD setup time optimiser provides a solution for almost any clamping task in plate forming, plastics and rubber processing. The magnetic, hydraulic and electro-mechanical clamping systems can be used in a variety of applications and contribute to more efficient and economical processes in the batch and series production of almost any industry. Die changing products, including, but not limited to changing carts, roller bars and driven carrying consoles, supplement the offer.

About ROEMHELD:

Whether aircraft, automobiles, machine tools or smartphone casings: The ROEMHELD Group technologies and products have been used in the manufacture of a variety of industrial goods and products for end consumers for over 60 years.

Efficient clamping technology solutions for workpieces as well as for forming dies and moulds in plastics processing are the core of the continuously growing portfolio. It is supplemented by components and systems for installation and handling technology, drive system technology, as well as locking systems for the rotors of wind power stations.

Apart from a broad range of about 20,000 catalogue items, the ROEMHELD Group specialised in the development and manufacture of customised solutions and is recognised as a worldwide market and quality leader.

Innovation by tradition: ROEMHELD have their origin in the Friedrichshütte foundry established in 1707; it is still part of the ROEMHELD Group and one of the oldest active industrial enterprises in Germany.

The owner-managed group of companies has about 560 employees at the three locations Laubach, Hilchenbach and Rankweil/Austria, and is represented by service and distribution companies in over 50 countries. With customers primarily in the mechanical, automotive, aerospace and agricultural industry, the ROEMHELD Group generates sales of over EUR 100 million annually.

Leave A Comment

You must be logged in to post a comment.