Are you interested in streamlining your production and lowering your costs? Find out how this can be achieved with our multi-tool for effective flanging here.

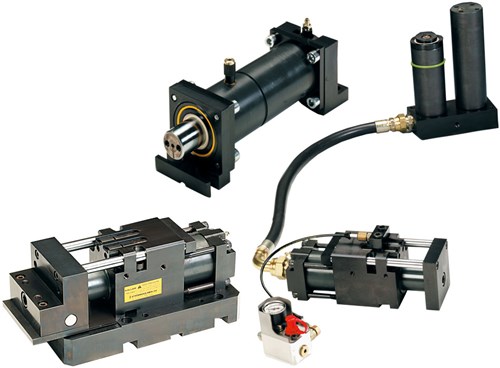

With smart, simplified tool design KALLER has made it possible to combine functions in already existing dies. The customer, in this case, asked for a more efficient, and cost-effective way to perform the flanging operation on a support beam. By applying our product, the KALLER Flex Cam, we developed a solution to implement flanging into the existing piercing/trimming operation and merge them into one. Not only did we optimize the production line, but also reduced the customers’ production costs.

Curious to find out more? Read the full case story here. This is one of many examples of how we can make your production more efficient. Get in touch and let us know what problem we can solve for you.

The KALLER Flex Cam has become a standard component for many vehicle manufacturers and is often included in different vehicle manufacturing tool standards globally.

The system has, with proper set-up, performed more than two million cycles without any servicing required. Learn more about the product here.

Leave A Comment

You must be logged in to post a comment.