- Voith provides high-performance variable speed drive for 240-tonne hydraulic punching machine from Schoen + Sandt

- Energy savings up to 70 per cent

- Comprehensive system approach for maximum performance

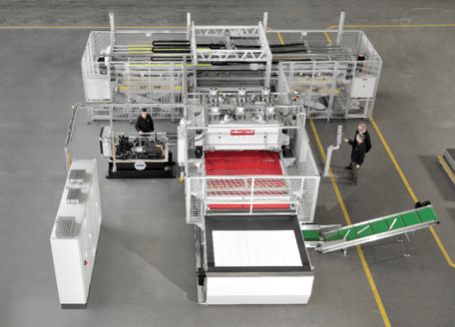

Schoen-Sandt´s type 5050 hydraulic large area punching machine.

Heidenheim, German Voith is supporting machine manufacturer Schoen + Sandt in implementing state-of-the-art servo technology in a 240-tonne large area punching machine. The manufacturer is contributing a variable speed drive to meet Schoen + Sandt’s requirements in terms of cycle numbers, speed, die-cut quality, accuracy and energy efficiency.

Developed for punching floor coverings, Schoen + Sandt’s Type 5050 hydraulic large area punching machine has a punching area of 2,200 mm to 1,600 mm to and a stroke of 165 mm. The machine achieves an impressive cutting force of 2,400 kN. For maximum productivity, it is equipped with an automatic tool clamping system. Other features include a centring device for positioning the sheet material on the roller conveyor, a double execution of the material application device as well as an intelligent punching belt system. In addition to servo pump technology, conventional hydraulics, for example for driving secondary actuators, are also used on the unit.

Variable speed drive for reduced complexity

To meet the high control requirements of a hydraulic system as complex as this, Schoen + Sandt turned to long-time collaborator Voith: “In selecting our suppliers, we emphasise quality and energy efficiency,” says Ronald Michels, Head of Design at Schoen + Sandt. “The partner needs to understand the end customer’s application and provide an innovative solution. Voith fulfils these conditions.”

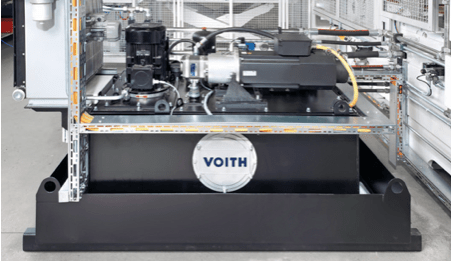

The Heidenheim-based company provided a state-of-the-art variable speed drive to regulate the pressure and volume flow and to convert the electrical energy into hydraulic energy for the system to utilise. Both in the part-load range and outside of the machine cycle, the drive operates at lower speeds or stands still. This results in energy savings of up to 70 per cent. Besides, the standard valve technology for the control of the punch stroke is eliminated – the entire hydraulic system is thus simplified considerably.

Comprehensive system expertise and full-service implementation

Due to a holistic system approach, all components of Voith’s servo pump drive are perfectly matched to ensure maximum performance of Schoen+Sandt’s large area punching machine.

Given Voith’s holistic system approach, all components are perfectly matched to ensure maximum performance. To power the servo pump as well as the conventional hydraulics, Voith has also delivered an intelligent and energetically optimised storage charging technology. The entire collaboration was deemed a great success: “From the determination of the technical parameters to the implementation of the servo technology, Voith supported us throughout the entire project,” summarises Ronald Michels.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Turbo is part of the Voith Group and a specialist for intelligent drive technology, systems as well as tailor-made services. With its innovative and smart products, Voith offers highest efficiency and reliability. Customers from highly diverse industries such as oil and gas, energy, mining and mechanical engineering, ship technology, rail and commercial vehicles rely on the advanced technologies and digital applications of Voith.

Leave A Comment

You must be logged in to post a comment.