Chairman’s Update from the over the last few months.

Dear Members,

Firstly, I hope you’re all well and safe and making the best of the new now! We at the MMMA have been keeping you up to date with the latest industry and manufacturing developments re: Covid-19 and what we are doing for our sector, promoting your individual companies with our social media shout outs.

This year albeit a very strange one, has appeared to fly by its October wow! We are seeing the economy starting to recover with the automotive industry getting back on its feet, as car sales rise which is positive news. Somehow though, I feel we are not out of the woods yet as covid is trying to hit back and looming round the corner is Brexit !

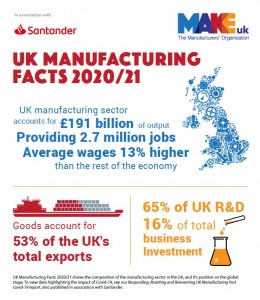

But for now the general news for manufacturing is good, some of which I will you will find at the end of this update, so it’s not all doom and gloom. It’s important to remember that manufacturing is the key to any economy, so we must keep pushing forward.

As you may be aware we have had no meetings because of obvious reasons. Now a question, what do you feel about a meeting say in mid October / November at a selected Hotel, abiding by social distance rules etc OR a zoom meeting please let us know?

As regards to the MMMA, you will be pleased to know we are all up and running with accounts now. Kate has done a great job and here at the MMMA we have now introduced internet banking and all the rest of it! You should all have had your money back from MACH2020, and unfortunately there will be no MACH next year, as it’s all going to be in 2022, which is the best for lots of reason in my opinion. We look forward to seeing you at MACH2022.

We really appreciate your feed back on anything todo with manufacturing MMMA social media projects new machines anything thats good news technical interesting so we can share with all of us as per below of one of our members which is nice to see.

Member Quote:- ‘It has been as asset receiving up-to date briefs from the MMMA and Associates along with the government briefs, as these have been specifically relevant to our sector and save trawling through literally hundreds of emails etc.’

All that remains to be said is keep safe and well and we are looking forward to hearing from you rememeber its your organisation you only get out what you put in. Assuring you of our best intentions at all times. Stay safe.

In the past we have featured Good News Stories from around the various manufacturing industries in the UK and we feel this is something that we should continue to share.

During recent months, there are many reasons to celebrate UK Manufacturing and the efforts numerous Companies around the Country continue to make, in order to ensure the economy bounces back and becomes stronger than ever.

Please feel free to share these stories and news articles from recent months and keep pushing to get the message out there loud and clear – UK Manufacturing is Great, Britain is Great!

McLaren’s next generation of supercars to be engineered in Rotherham

The new vehicle architecture, designed specifically to accommodate new hybrid powertrains, has been entirely engineered, developed and produced in-house in the UK at McLaren’s £50m state-of-the-art McLaren Composites Technology Centre (MCTC) at Rotherham. Mike Flewitt, CEO of McLaren Automotive, confirmed the introduction of the brand’s all-new, flexible, lightweight vehicle architecture would enable McLaren to transition to 100 per cent electrified supercars.

The new flexible vehicle architecture utilises innovative, world-first processes and techniques to strip out excess mass, reduce overall vehicle weight, while also further improving safety.

It will underpin the next generation of McLaren hybrid models as the supercar company enters its second decade of series vehicle production.

£9.5m investment for 5G industrial testbed

Manufacturing in the North West received a massive confidence boost with the announcement of almost £10m public and private investment in an open access 5G industrial testbed, led by the University of Sheffield Advanced Manufacturing Research Centre (AMRC).

The 5G-Factory of the Future programme is set to be based primarily at the AMRC’s soon-to-be-built facility on the Salmesbury Enterprise Zone, and will enhance Lancashire and the North West’s reputation as a hot-bed of advanced manufacturing innovation and expertise.

The £9.5m award, which includes match funding from industry, was made by the Department for Digital, Culture, Media and Sport (DCMS) and is part of the government’s £200m investment in 5G test bed facilities across the country.

“This is a big vote of confidence in Lancashire and the North West and a potential game changer for the region,” said Melissa Conlon, commercial director for AMRC North West, whose team, part of the High Value Manufacturing Catapult, led an industrial consortium that includes global players such as BAE Systems, IBM, and telecoms and private 5G network provider, Three, along with Burnley-based MTT, an SME developer of digitalisation technologies for machine tools, and the Lancashire-based data-driven logistics specialist Miralis. The Digital Catapult will be the technical authority lead and coordinate 5G integration, working closely with Three and use case developers.

New manufacturing institute to unlock collaboration and boost UK economy

The National Physical Laboratory (NPL) has secured £50k early-stage funding for the Advanced Machinery and Productivity (AMP) Institute in Rochdale. The funding has been awarded through the UK’s Industrial Strategy Challenge Fund (ISCF) Strength in Places Fund (SIPF).

Driving innovation for the UK’s advanced machinery manufacturers, the AMP Institute will create the new machines and engineers needed to manufacture tomorrow’s technologies.

The AMP Institute will be centred around existing capabilities and research excellence across the North of England and reaching across the wider UK, to establish and develop economic growth in the design, development and manufacture of advanced machinery and robotic systems.

Providing a safe space, technical resources and the skills pipeline needed for advanced machinery innovation to flourish, the AMP Institute will fulfil a presently unaddressed, yet critical aspect, of the UK’s manufacturing innovation infrastructure.

UK manufacturing output grows at fastest pace since 2014

UK manufacturing sector output grew at its fastest pace since May 2014 last month, as the easing of coronavirus restrictions prompted firms to rapidly scale up production.

A closely watched survey by IHS Markit found that the sector’s purchasing managers’ index reading came in at 55.2 in August, broadly in line with expectations.

The figure, up from 53.3 in July and well above April’s record low of 32.6, indicates the fastest pace of overall growth within the sector since February 2018.

PMIs are an indicator of private sector activity and are given on a scale of 1 to 100. Anything above 50 signals growth, while anything below means contraction.

The rapid increase in output reflected “solid expansions” across several sub-sectors, according to IHS Markit.

The sector saw the biggest increase in new orders since November 2017, with the domestic market serving as a “prime source” of new contract wins, it said.

New orders from export markets also rose for the first time in 10 months, with firms reporting improved demand from the Europe, Middle East and Africa (EMEA) region, North America, and Australia.

“The recovery of the UK manufacturing sector gathered pace in August. Output expanded at the fastest rate in over six years as new work intakes rose to the greatest extent since November 2017, led by an upturn in domestic demand and signs of recovering exports,” said Rob Dobson, a director at IHS Markit.

Leave A Comment

You must be logged in to post a comment.